Tag: Quality

-

Medical Device EMS: The Backbone of Modern Healthcare Innovation

In today’s rapidly evolving healthcare landscape, the role of Electronics Manufacturing Services (EMS) in the medical device industry cannot be overstated. With the increasing complexity of medical devices, ranging from wearable health monitors to advanced diagnostic tools, the need for precision, reliability, and speed in production is critical. As healthcare systems worldwide continue to modernize,…

-

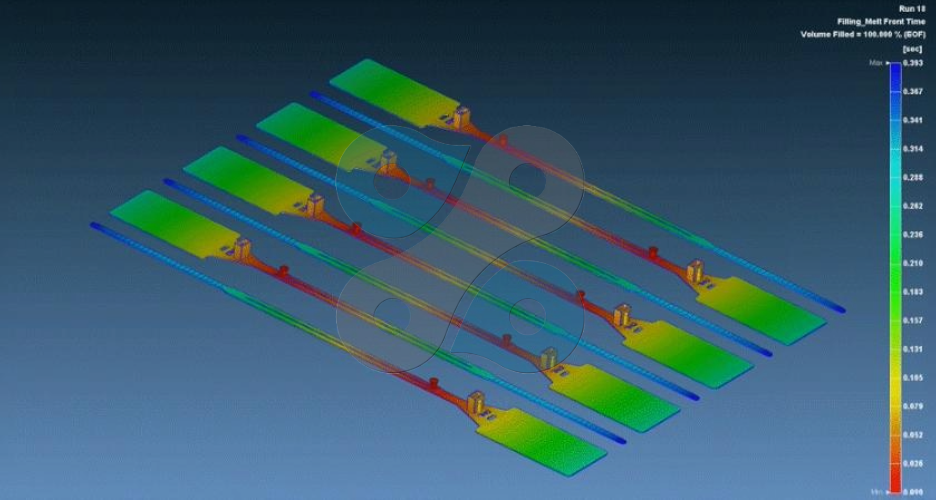

Mold Flow Analysis: A Key Driver for Innovation and Efficiency in Injection Moulding

In the ever-evolving landscape of manufacturing, mold flow analysis has emerged as a pivotal tool for driving innovation and efficiency in the injection molding process. As a sophisticated simulation technique, mold flow analysis allows manufacturers to predict and optimize the flow of molten material within a mold cavity, ensuring superior product quality and reduced manufacturing…

-

Choosing the Right EMS Provider for IoT Product Owners: Key Considerations

As the Internet of Things (IoT) continues to transform industries, IoT product owners face the challenge of turning innovative ideas into fully functional, market-ready devices. One of the most crucial decisions an IoT product owner will make is selecting the right Electronics Manufacturing Services (EMS) provider. With the increasing complexity of IoT devices and the…

-

Automotive Electronics Manufacturing Services: Key to Meeting Industry Demands

The automotive industry is undergoing a dramatic transformation, with electronic components becoming integral to vehicle functionality. From infotainment systems to safety mechanisms and the critical components of electric vehicles (EVs), automotive electronics are at the core of this revolution. The manufacturing of these components requires precision, reliability, and cutting-edge technology, which makes Electronics Manufacturing Services…

-

From Concept to Reality: The Advanced Moulding Process at Vohrum’s ISO Class-8 Clean Room Facility

In the competitive landscape of medical device production, Vohrum offers unparalleled expertise in clean room injection moulding through its ISO Class-8 clean room facility. This is a testament to Vohrum’s commitment to precision and quality, ensuring that every product meets the stringent demands of the healthcare industry. By leveraging cutting-edge cleanroom technology, Vohrum not only…

-

The Importance of Minimizing Sink Mark Defect: Enhancing the Visual Appeal and Durability of Your Products

In the intricate world of manufacturing, particularly in injection moulding, the presence of sink marks can significantly impact both the aesthetic and functional quality of a product. A sink mark, often perceived as a cosmetic defect, occurs when the surface of the plastic part shows sunken areas due to uneven cooling or insufficient packing pressure…

-

How to Get FCC Certification, Why FCC, and Benefits for Contract Manufacturers

For startups and product designers venturing into the world of product development, FCC certification is an essential step toward bringing your product to market, especially if you’re working with IoT devices or medical devices. But navigating the FCC certification process can be a daunting task without the right expertise. Fortunately, partnering with a contract development…

-

Revolutionizing Precision Measurement for Rubber Parts with CT Scan

The Challenge: Understanding Rubber Part Requirements and Tolerances Customer X, a precision injection molder, faced significant challenges in understanding the part requirements of a rubber part, tolerances, and the ability to meet these stringent demands set by their end-customer of a rubber part. However we helped them with a CT Scanning of the rubber parts…

-

Why Moldflow Analysis is Crucial in the Design for Manufacturing Process: Insights from Vohrum

Moldflow analysis stands as a pivotal component in the design for manufacturing (DFM) process, particularly within the realm of injection molding. This advanced simulation technique enables engineers to predict and optimize the flow of molten plastic within molds, ensuring that the final product meets stringent quality and performance standards. By leveraging mold flow analysis services,…

-

Achieving Precision in 3D Printing: A Guide to Managing Material Properties and Shrinkage Challenges

In the realm of 3D printing, achieving precision is a critical goal for professionals seeking to enhance manufacturing accuracy and ensure optimal dimension control. As the industry continues to evolve, understanding the intricacies of material properties and managing part shrinkage becomes paramount. This guide delves into the challenges of thermal contraction and plastic deformation, providing…

-

Understanding Sink Marks in Injection Moulding: Impact on Product Aesthetics and Quality

Sink marks in injection moulding represent a common yet critical defect that can significantly impact the aesthetics and quality of the final product. These depressions occur on the surface of a molded part when the shrinkage of the inner material is not compensated during the cooling process, leading to uneven surfaces and potential structural weaknesses.…

-

The Precision of Moldflow Analysis in Injection Moulding: A Deep Dive for Industry Innovators

In the ever-evolving landscape of manufacturing, the precision of mold flow analysis in injection molding is a game-changer for industry innovators seeking to refine their production processes. Mold flow analysis is a critical component of the design for manufacturing process that allows engineers to predict how melted plastic will behave in a mold cavity, ensuring…

-

Revolutionizing Quality Control With CT-Scanning

In the ever-evolving landscape of quality control and precision engineering, a our Zeiss Metrotom 1 stands out as a game-changer powered by cutting-edge computed tomography technology. This compact yet powerful 3D scanning solution offers unmatched ease of use and precision, enabling users to inspect internal structures and detect hidden defects with no part preparation required.…

-

Mastering Process Robustness: The Role of Concurrent Engineering in Plastic Injection Moulding

In the competitive world of manufacturing, achieving process robustness in plastic injection moulding is a pivotal factor for ensuring part quality consistency and manufacturing efficiency. Concurrent engineering emerges as a key strategy for addressing the complex challenges inherent in the moulding process, facilitating seamless collaboration across design, engineering, and production teams. By integrating concurrent engineering…