Tag: Injection Moulding

-

Mold Flow Analysis: A Key Driver for Innovation and Efficiency in Injection Moulding

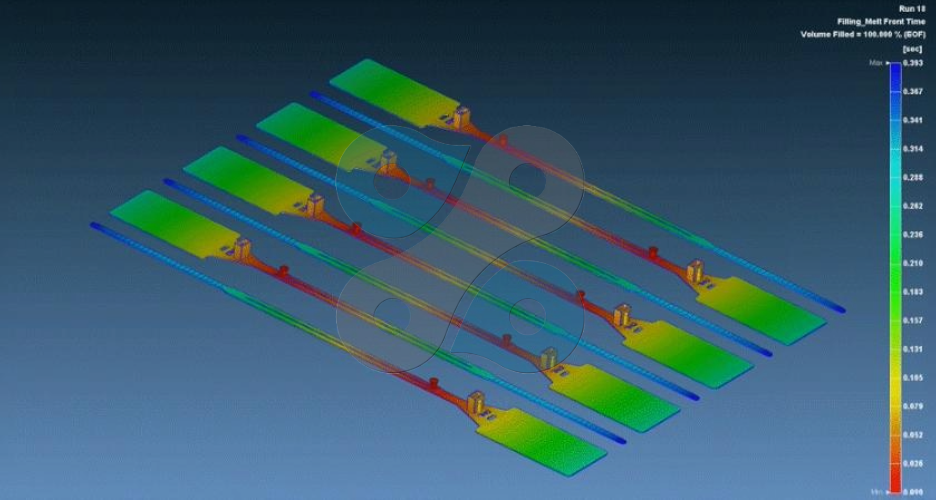

In the ever-evolving landscape of manufacturing, mold flow analysis has emerged as a pivotal tool for driving innovation and efficiency in the injection molding process. As a sophisticated simulation technique, mold flow analysis allows manufacturers to predict and optimize the flow of molten material within a mold cavity, ensuring superior product quality and reduced manufacturing…

-

From Concept to Reality: The Advanced Moulding Process at Vohrum’s ISO Class-8 Clean Room Facility

In the competitive landscape of medical device production, Vohrum offers unparalleled expertise in clean room injection moulding through its ISO Class-8 clean room facility. This is a testament to Vohrum’s commitment to precision and quality, ensuring that every product meets the stringent demands of the healthcare industry. By leveraging cutting-edge cleanroom technology, Vohrum not only…

-

The Importance of Minimizing Sink Mark Defect: Enhancing the Visual Appeal and Durability of Your Products

In the intricate world of manufacturing, particularly in injection moulding, the presence of sink marks can significantly impact both the aesthetic and functional quality of a product. A sink mark, often perceived as a cosmetic defect, occurs when the surface of the plastic part shows sunken areas due to uneven cooling or insufficient packing pressure…

-

Unlocking Innovation: Exploring the Types of Snap Fits for Cutting-Edge Plastic Assembly Techniques

In the realm of modern manufacturing, snap fit design emerges as a pivotal element, streamlining plastic assembly techniques with precision and efficiency. As manufacturers, product designers, and engineers strive to innovate, understanding the diverse types of snap fits becomes essential for advancing product development. These versatile connectors offer numerous benefits, including cost-effectiveness, ease of assembly,…

-

Why Moldflow Analysis is Crucial in the Design for Manufacturing Process: Insights from Vohrum

Moldflow analysis stands as a pivotal component in the design for manufacturing (DFM) process, particularly within the realm of injection molding. This advanced simulation technique enables engineers to predict and optimize the flow of molten plastic within molds, ensuring that the final product meets stringent quality and performance standards. By leveraging mold flow analysis services,…

-

Understanding Sink Marks in Injection Moulding: Impact on Product Aesthetics and Quality

Sink marks in injection moulding represent a common yet critical defect that can significantly impact the aesthetics and quality of the final product. These depressions occur on the surface of a molded part when the shrinkage of the inner material is not compensated during the cooling process, leading to uneven surfaces and potential structural weaknesses.…

-

Unlocking the Benefits of Snap Fit Assembly for Innovative Plastic Product Design

In today’s fast-paced world of manufacturing and product design, the demand for innovative and efficient assembly techniques has never been higher. As companies seek welding alternatives for plastics and strive to reduce reliance on traditional fastening methods, snap fit design emerges as a promising solution. This technique, which involves the interlocking of plastic parts without…

-

The Precision of Moldflow Analysis in Injection Moulding: A Deep Dive for Industry Innovators

In the ever-evolving landscape of manufacturing, the precision of mold flow analysis in injection molding is a game-changer for industry innovators seeking to refine their production processes. Mold flow analysis is a critical component of the design for manufacturing process that allows engineers to predict how melted plastic will behave in a mold cavity, ensuring…

-

Mastering Process Robustness: The Role of Concurrent Engineering in Plastic Injection Moulding

In the competitive world of manufacturing, achieving process robustness in plastic injection moulding is a pivotal factor for ensuring part quality consistency and manufacturing efficiency. Concurrent engineering emerges as a key strategy for addressing the complex challenges inherent in the moulding process, facilitating seamless collaboration across design, engineering, and production teams. By integrating concurrent engineering…

-

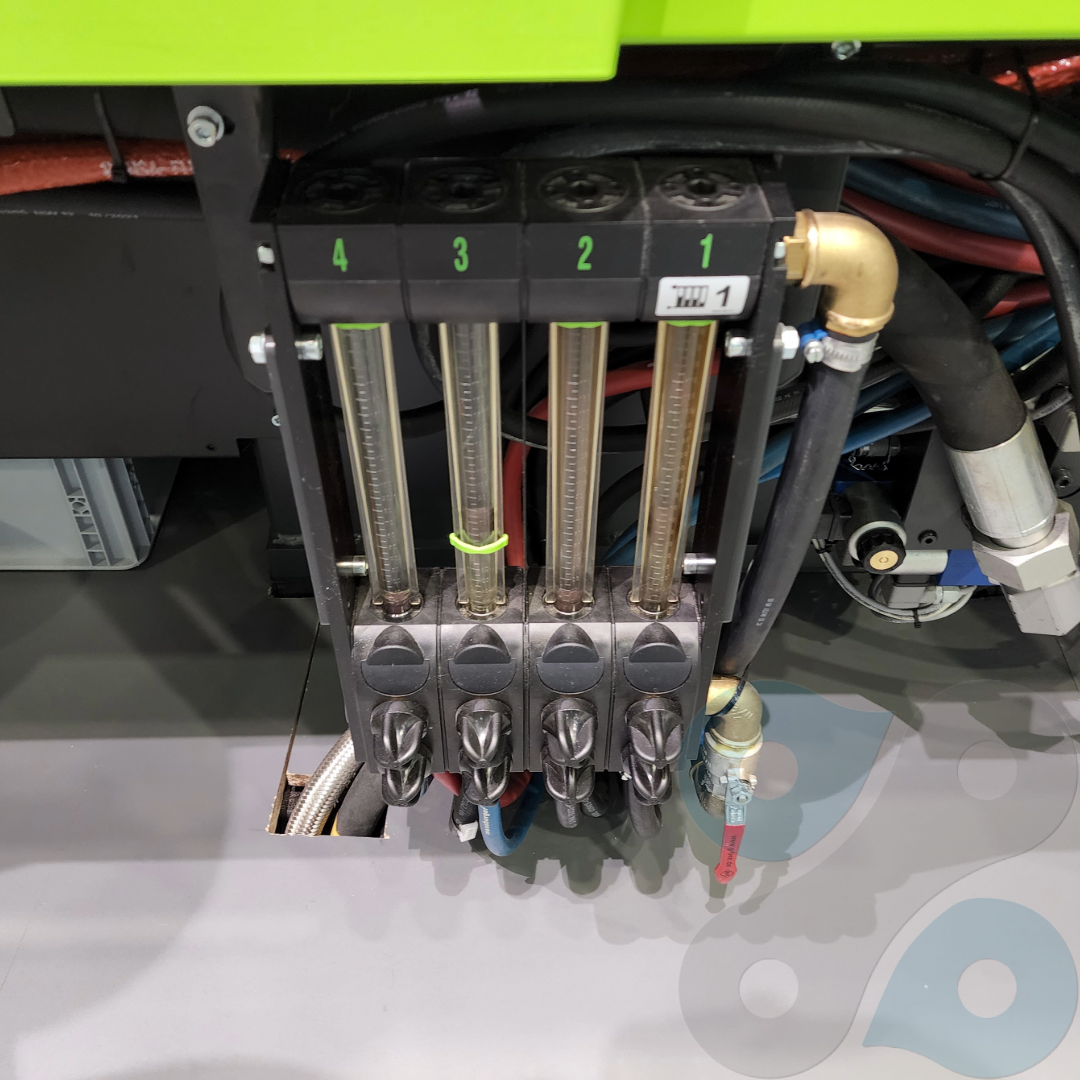

Unlocking Excellence: How Optimized Cooling Transforms Injection Moulding for Superior Quality and Speed

In the competitive world of plastic manufacturing, the cooling process in injection moulding stands as a pivotal factor influencing both the quality and speed of production. By optimizing this phase, manufacturers can achieve significant improvements in manufacturing efficiency and dimensional accuracy, ultimately leading to superior molded parts quality. Properly managed cooling reduces production speed and…

-

Navigating the Malaysian Plastic Injection Moulding Landscape: Insights for Manufacturers and Procurement Experts

Navigating the intricate landscape of Malaysia’s plastic injection moulding industry requires a blend of expertise, innovation, and strategic insight. As a pivotal hub for plastic production, Malaysia stands out with its advanced injection moulding services, cutting-edge mould making techniques, and robust plastic manufacturing capabilities. For manufacturers and procurement experts, understanding the nuances of this sector…

-

The Science Behind Perfection: Elevating Product Development with Advanced Injection Molding Techniques

In the ever-evolving landscape of product development, achieving perfection is not just an aspiration but a necessity for maintaining competitive advantage. The advent of scientific molding has revolutionized the way manufacturers optimize their molding techniques, leading to enhanced product quality and efficiency in manufacturing processes. By employing precise data-driven methodologies, scientific molding allows for meticulous…

-

Achieving Superior Quality: The Role of Moldflow Analysis in Injection Moulding

Achieving superior quality in injection moulding necessitates a strategic focus on design for manufacturability, and this is where moldflow analysis proves indispensable. Moldflow analysis allows engineers to simulate the plastic injection moulding process, identifying potential issues and optimizing designs before production begins. By leveraging this advanced technology, companies can ensure excellence in product quality, reduce…

-

How CT Scanning allows for accurate and permanent digital representation of the scanned part

CT scanning in industrial applications allows for digital representation of the scanned part by converting a physical part to 3D. This process offers various benefits that contribute to improved efficiency, accuracy, and quality in manufacturing and inspection processes. Digital copies of CT scans can be archived for future reference, providing a comprehensive record of inspection…