Tag: Design and Development

-

Medical Device EMS: The Backbone of Modern Healthcare Innovation

In today’s rapidly evolving healthcare landscape, the role of Electronics Manufacturing Services (EMS) in the medical device industry cannot be overstated. With the increasing complexity of medical devices, ranging from wearable health monitors to advanced diagnostic tools, the need for precision, reliability, and speed in production is critical. As healthcare systems worldwide continue to modernize,…

-

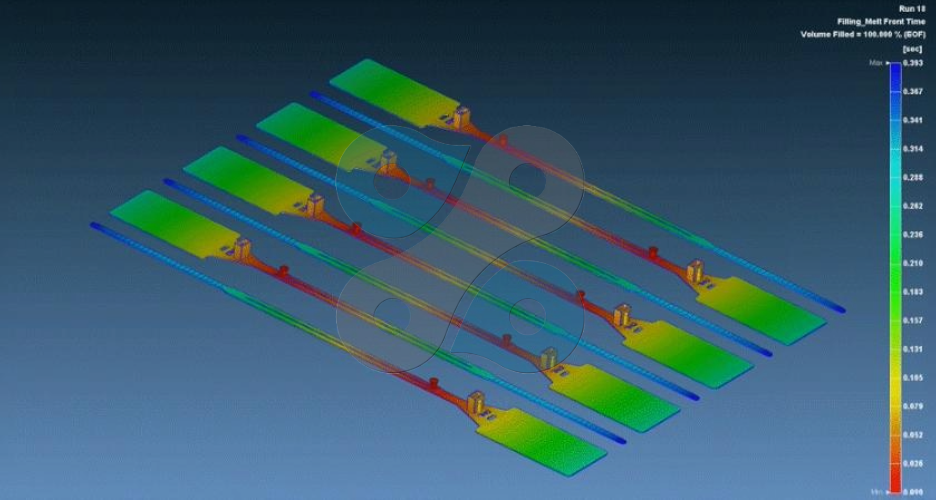

Mold Flow Analysis: A Key Driver for Innovation and Efficiency in Injection Moulding

In the ever-evolving landscape of manufacturing, mold flow analysis has emerged as a pivotal tool for driving innovation and efficiency in the injection molding process. As a sophisticated simulation technique, mold flow analysis allows manufacturers to predict and optimize the flow of molten material within a mold cavity, ensuring superior product quality and reduced manufacturing…

-

Choosing the Right EMS Provider for IoT Product Owners: Key Considerations

As the Internet of Things (IoT) continues to transform industries, IoT product owners face the challenge of turning innovative ideas into fully functional, market-ready devices. One of the most crucial decisions an IoT product owner will make is selecting the right Electronics Manufacturing Services (EMS) provider. With the increasing complexity of IoT devices and the…

-

Navigating the Product Development Process: How Vohrum Delivers Innovative Solutions for Entrepreneurs

Navigating the intricate product development process requires expertise and innovation, and Vohrum stands as a leader in delivering these innovative solutions for entrepreneurs. By expertly guiding clients through critical stages such as market research, rapid prototyping, and rigorous testing, Vohrum ensures that each product aligns with consumer needs and achieves market success. Utilizing advanced techniques…

-

How to Get FCC Certification, Why FCC, and Benefits for Contract Manufacturers

For startups and product designers venturing into the world of product development, FCC certification is an essential step toward bringing your product to market, especially if you’re working with IoT devices or medical devices. But navigating the FCC certification process can be a daunting task without the right expertise. Fortunately, partnering with a contract development…

-

Revolutionizing Precision Measurement for Rubber Parts with CT Scan

The Challenge: Understanding Rubber Part Requirements and Tolerances Customer X, a precision injection molder, faced significant challenges in understanding the part requirements of a rubber part, tolerances, and the ability to meet these stringent demands set by their end-customer of a rubber part. However we helped them with a CT Scanning of the rubber parts…

-

Unlocking Innovation: Exploring the Types of Snap Fits for Cutting-Edge Plastic Assembly Techniques

In the realm of modern manufacturing, snap fit design emerges as a pivotal element, streamlining plastic assembly techniques with precision and efficiency. As manufacturers, product designers, and engineers strive to innovate, understanding the diverse types of snap fits becomes essential for advancing product development. These versatile connectors offer numerous benefits, including cost-effectiveness, ease of assembly,…

-

Why Moldflow Analysis is Crucial in the Design for Manufacturing Process: Insights from Vohrum

Moldflow analysis stands as a pivotal component in the design for manufacturing (DFM) process, particularly within the realm of injection molding. This advanced simulation technique enables engineers to predict and optimize the flow of molten plastic within molds, ensuring that the final product meets stringent quality and performance standards. By leveraging mold flow analysis services,…

-

Achieving Precision in 3D Printing: A Guide to Managing Material Properties and Shrinkage Challenges

In the realm of 3D printing, achieving precision is a critical goal for professionals seeking to enhance manufacturing accuracy and ensure optimal dimension control. As the industry continues to evolve, understanding the intricacies of material properties and managing part shrinkage becomes paramount. This guide delves into the challenges of thermal contraction and plastic deformation, providing…

-

Understanding Sink Marks in Injection Moulding: Impact on Product Aesthetics and Quality

Sink marks in injection moulding represent a common yet critical defect that can significantly impact the aesthetics and quality of the final product. These depressions occur on the surface of a molded part when the shrinkage of the inner material is not compensated during the cooling process, leading to uneven surfaces and potential structural weaknesses.…

-

Navigating the Future: Sustainable Manufacturing and R&D in Malaysia’s Life Sciences Sector

As the global life sciences and medical technology industry gains momentum in the post-pandemic landscape, Malaysia emerges as a pivotal player, particularly in sustainable manufacturing and research and development (R&D). The country is strategically positioned to become an ASEAN medical devices hub, leveraging its innovative design and engineering capabilities to produce advanced medical technology solutions,…

-

Transform Your Product Development with Vohrum’s 3D Printing: Achieve Rapid Prototyping Success

In today’s fast-paced market, the ability to swiftly turn ideas into tangible products is a vital competitive advantage. Vohrum is at the forefront of innovation with its cutting-edge 3D printing solutions, designed to accelerate your product development process and achieve rapid prototyping success. By leveraging state-of-the-art additive manufacturing technologies, we empower product developers, entrepreneurs, and…

-

Unlocking the Benefits of Snap Fit Assembly for Innovative Plastic Product Design

In today’s fast-paced world of manufacturing and product design, the demand for innovative and efficient assembly techniques has never been higher. As companies seek welding alternatives for plastics and strive to reduce reliance on traditional fastening methods, snap fit design emerges as a promising solution. This technique, which involves the interlocking of plastic parts without…

-

The Ultimate Guide to Prototype Techniques: Weighing the Pros and Cons for Plastic Parts

In the ever-evolving landscape of manufacturing and design, selecting the right prototype techniques for plastic parts is crucial for product owners, engineers, designers, and manufacturers. With a myriad of options available, including 3D printing, CNC machining, prototype tooling for injection moulding, and vacuum casting, it becomes essential to weigh the pros and cons of each…

-

The Precision of Moldflow Analysis in Injection Moulding: A Deep Dive for Industry Innovators

In the ever-evolving landscape of manufacturing, the precision of mold flow analysis in injection molding is a game-changer for industry innovators seeking to refine their production processes. Mold flow analysis is a critical component of the design for manufacturing process that allows engineers to predict how melted plastic will behave in a mold cavity, ensuring…