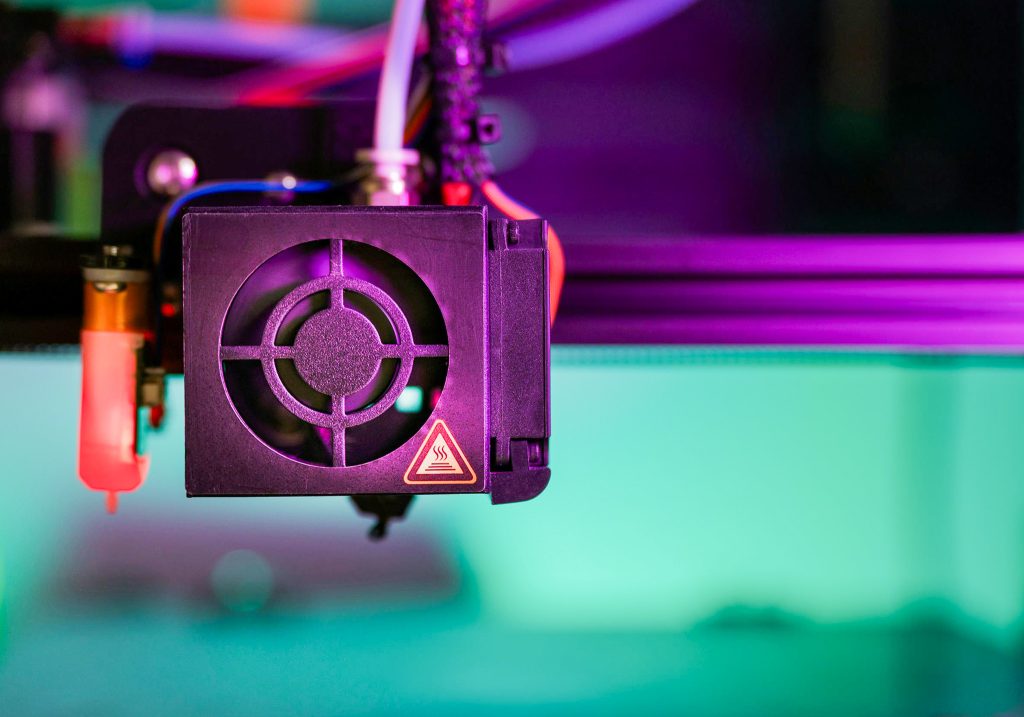

在当今快节奏的市场中,将创意迅速转化为有形产品的能力是一项至关重要的竞争优势。Vohrum 凭借其尖端的 3D 打印解决方案走在创新的前沿,旨在加速您的产品开发流程并实现快速原型设计的成功。通过利用最先进的增材制造技术,我们使产品开发人员、企业家和初创公司能够高效地创建精确且经济高效的 3D 打印原型和原型部件。我们的专业知识不仅可以将您的概念设计转化为现实,还可以激发您对产品潜力的信心和信任。在此过程中,马来西亚的 3D 打印可以在促进本地制造解决方案方面发挥关键作用。

革命性的产品开发

利用 3D 打印技术

3D 打印技术正在改变各行各业的产品开发方式。通过快速成型,开发人员可以快速创建、测试和改进原型部件,而无需传统制造过程中的漫长延迟。这种方法不仅加速了产品开发过程,而且还通过最大限度地减少材料浪费和人工费用显著降低了成本。例如,马来西亚 3D 打印的进步帮助许多企业提高了生产周期的效率。此外,3D 打印原型提供无与伦比的精度,确保准确捕获和评估复杂的设计。借助增材制造的灵活性,可以定制和调整产品以满足特定客户需求或适应市场需求的变化。此外,生产传统方法难以实现的复杂几何形状的能力为设计师和工程师提供了更广泛的创新空间。因此,利用 3D 打印技术彻底改变了产品开发流程,使其更加高效、适应性更强、更具创造力。

实现快速原型制作的成功

实现快速原型制作的成功取决于能否快速迭代和改进设计以满足精确的规格。利用 3D 打印技术,开发人员可以在传统方法所需时间的一小部分内制作和评估原型的多个版本。在竞争激烈的市场中,这种速度至关重要,因为上市时间是产品成功的决定性因素。在马来西亚广泛使用 3D 打印的地区,企业已经看到了快速原型制作结果的改善。将增材制造集成到原型制作过程中还可以获得即时反馈,使设计师能够快速调整和改进。此外,使用多种材料制作功能原型的能力意味着可以在真实条件下测试产品,从而提供有关性能和耐用性的宝贵见解。这种迭代过程不仅提高了最终产品的质量,而且还让利益相关者相信最终结果将达到或超过预期。最终,使用 3D 打印进行快速原型制作可以促进创新并更快地将优质产品推向市场。

增材制造的优势

原型设计的速度和效率

增材制造因其能够提高原型制作速度和效率而闻名。与通常涉及多个步骤和较长交付周期的传统制造方法不同,3D 打印通过将数字设计直接转换为物理模型,简化了流程。此功能允许快速生产原型部件,大大缩短了从概念到创造的时间。此外,增材制造的效率在于它能够生产复杂的几何形状,而无需专门的工具或模具,从而节省时间和资源。3D 打印带来的快速周转实现了快速迭代和测试,使设计师能够根据反馈和性能评估快速改进其产品。在马来西亚等地区,3D 打印正在成为马来西亚的关键产业,这些好处尤为明显。此外,该技术支持更敏捷的开发流程,可以在不停止生产的情况下即时进行调整。通过利用增材制造的速度和效率,公司可以保持竞争优势并更快地将创新产品推向市场。

创建高质量原型部件

制造高品质原型零件是增材制造的根本优势。3D 打印技术的精确性确保了复杂的细节和几何形状能够精确再现,从而制作出与最终产品非常相似的原型。这种细节水平对于测试形状、配合度和功能至关重要,可在开发阶段提供宝贵的见解。此外,增材制造支持使用各种材料,包括塑料、金属和复合材料,从而能够制造出不仅外观与预期最终产品相似而且性能也与预期最终产品相似的原型。这种多功能性确保原型经久耐用且可靠,可用于功能测试。此外,3D 打印固有的逐层结构允许对原型的密度和强度等属性进行精细控制,从而根据特定要求对其进行优化。总体而言,增材制造使开发人员能够生产高品质的原型零件,从而促进全面的评估和开发,最终生产出卓越的最终产品。马来西亚 3D 打印的持续进步促进了增材制造的全球增长和创新。

成功案例和客户评价

3D 打印原型的实际应用

在各个行业中,3D 打印原型已通过显著增强产品开发和创新证明了其价值。例如,在汽车行业,公司使用 3D 打印来创建发动机组件和内饰零件的功能原型,从而实现快速测试和改进。这种方法不仅加快了设计周期,而且还通过最大限度地减少对传统工具的需求来降低成本。在医疗领域,3D 打印原型用于开发定制植入物和手术工具,从而可以根据个人患者需求量身定制个性化医疗解决方案。这种定制可以改善患者的治疗效果并加快新医疗设备的审批流程。在消费电子产品中,快速成型有助于设计复杂的外壳和符合人体工程学的手持设备,确保它们满足用户的期望和监管标准。这些现实世界的应用强调了 3D 打印原型的变革性影响,突出了它们在推动不同行业效率、创新和成功方面的作用。随着马来西亚 3D 打印等新兴市场的出现,这项技术的采用不断扩大,并显示出令人鼓舞的成果。

为初创企业和企业家带来变革性成果

对于初创企业和企业家来说,3D 打印通过为产品开发创造公平的竞争环境,带来了变革性成果。这项技术使新企业能够快速将创意变为现实,无需在工具或制造设备上进行大量初始投资即可创建有形原型。通过实现快速迭代,初创企业可以根据客户反馈改进其产品,确保提供满足用户需求的市场解决方案。这种灵活性不仅可以加快开发过程,还可以降低风险,因为企业家可以在投入大规模生产之前测试和验证他们的概念。初创企业利用 3D 打印以创新产品颠覆传统行业的成功案例比比皆是。这种能力培养了创新和创造文化,使企业家能够与规模更大、更成熟的公司竞争,并最终在各自的市场中实现显着增长和成功。3D 打印在马来西亚的存在极大地促进了该地区新企业的发展。