In the fast-paced world of product design and development, the integration of 3D printing technology has revolutionized the way companies approach rapid prototyping and product development. This cutting-edge additive manufacturing technique offers myriad benefits, enabling engineers and designers to iterate quickly, reduce costs, and accelerate time-to-market. By harnessing the power of 3D printing, businesses can achieve unprecedented levels of precision, customization, and innovation in their prototyping processes. In this article, we will delve into the multifaceted advantages of 3D printing for rapid prototyping and product development, exploring how this transformative technology is reshaping industries and driving competitive advantage.

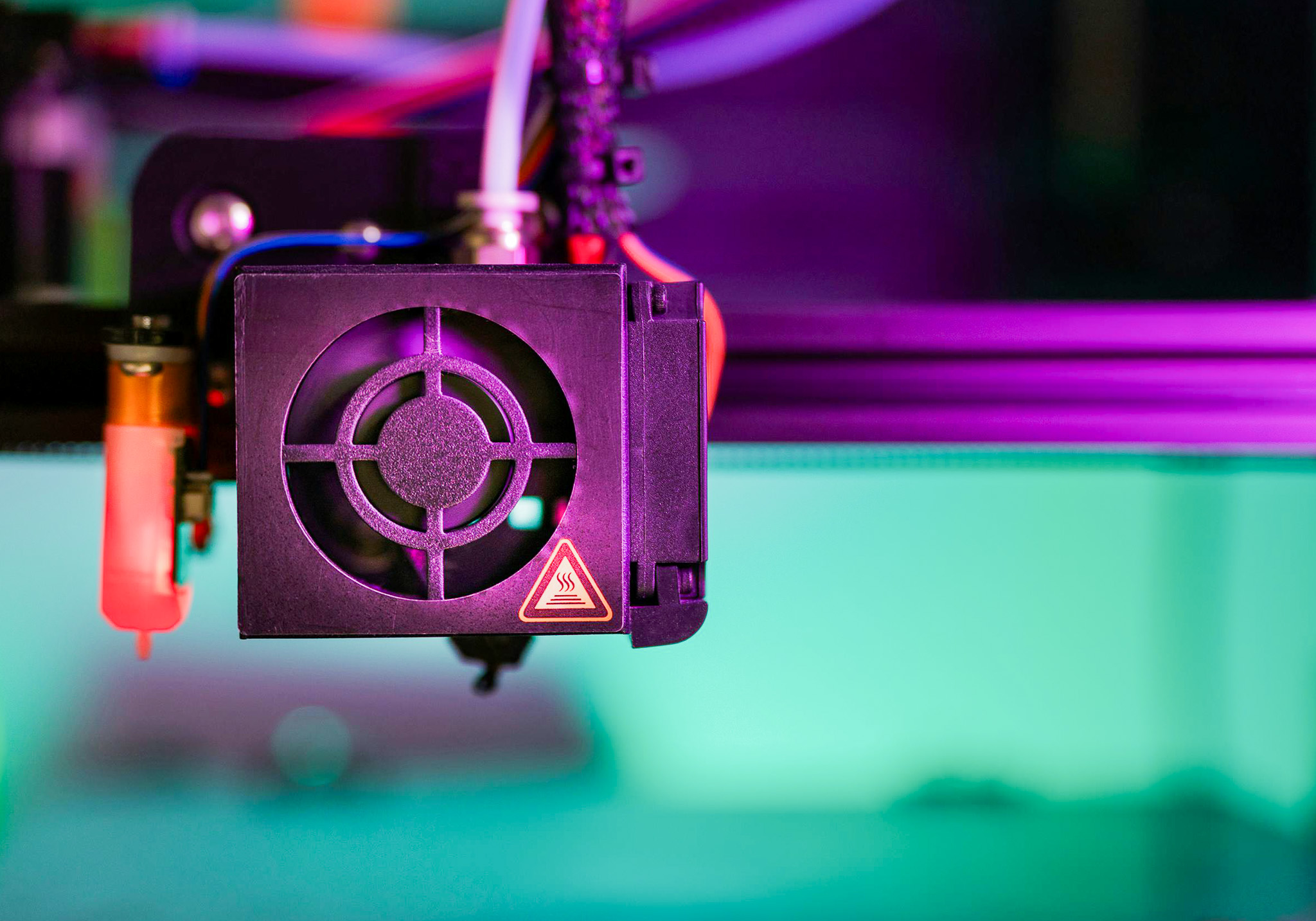

Introduction to 3D Printing

Evolution of Additive Manufacturing

Additive manufacturing, commonly known as 3D printing, has undergone significant evolution since its inception in the 1980s. Initially, it was primarily used for creating simple plastic prototypes. However, advancements in technology have expanded its capabilities and applications. Early methods like stereolithography (SLA) and selective laser sintering (SLS) paved the way for more sophisticated techniques such as fused deposition modeling (FDM) and digital light processing (DLP). Today, 3D printing encompasses a variety of materials, including metals, ceramics, and bio-materials, allowing for a broader range of applications. These advancements have moved 3D printing from a niche prototyping tool to a mainstream method for full-scale product development and even end-use manufacturing. The continuous innovation in additive manufacturing technologies underscores its transformative impact on industries ranging from healthcare to aerospace, making it an indispensable tool for modern engineers and designers.

Key Technologies in 3D Printing

Several key technologies underpin the capabilities of modern 3D printing. Fused Deposition Modeling (FDM) is one of the most widely used methods, ideal for creating durable and functional parts from thermoplastic materials. Stereolithography (SLA) uses a laser to cure liquid resin into solid parts, offering high precision and smooth surface finishes. Selective Laser Sintering (SLS) employs a laser to fuse powdered materials, enabling the production of complex geometries without the need for support structures. Digital Light Processing (DLP) is similar to SLA but uses a digital light projector to cure resin, allowing for faster print times. Additionally, advancements in metal 3D printing, such as Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM), have opened new possibilities in industries requiring high-strength components. Each technology offers distinct advantages, making 3D printing a versatile tool for various applications in rapid prototyping and product development.

Market Impact and Trends

The impact of 3D printing on the market is profound and continues to grow. Initially utilized primarily for rapid prototyping, 3D printing has expanded into full-scale production and end-use parts, revolutionizing industries such as aerospace, automotive, healthcare, and consumer goods. The ability to produce complex geometries and customized products on-demand has led to a significant reduction in lead times and manufacturing costs. Additionally, the rise of distributed manufacturing models, where production can be localized and scaled as needed, is reshaping supply chain dynamics. Emerging trends in 3D printing include the development of new materials, such as biocompatible and high-temperature-resistant polymers, as well as advancements in multi-material printing. The integration of artificial intelligence and machine learning to optimize print processes and improve quality control is also on the horizon. These trends highlight the ongoing evolution and increasing importance of 3D printing in modern manufacturing and product development.

Benefits of 3D Printing

Cost-Effective Prototyping Solutions

One of the most significant benefits of 3D printing is its cost-effectiveness in prototyping. Traditional manufacturing methods often require expensive molds and tooling, which can be prohibitive for small runs or iterative design processes. In contrast, 3D printing eliminates the need for these upfront costs, allowing designers and engineers to create prototypes directly from digital models. This not only reduces material waste but also significantly lowers production costs. Additionally, 3D printing enables rapid iteration, meaning prototypes can be produced, tested, and refined in a fraction of the time it would take using conventional methods. This accelerated process helps businesses bring products to market faster while keeping development expenses in check. The ability to produce prototypes on-demand also means that companies can respond more quickly to market feedback and evolving customer needs, enhancing their competitive edge.

Accelerating Product Development Timelines

3D printing significantly accelerates product development timelines, offering a substantial advantage in competitive markets. Traditional manufacturing processes can be time-consuming, often requiring weeks or even months for tooling and setup. In contrast, 3D printing allows for the direct creation of parts and prototypes from digital designs, drastically reducing lead times. This rapid turnaround enables faster testing and validation of design concepts, allowing for more iterations in a shorter period. Consequently, companies can swiftly move from initial concept to final product, reducing the time-to-market. Additionally, the ability to produce functional prototypes quickly means that design flaws can be identified and addressed early in the development cycle, further streamlining the process. By leveraging 3D printing, businesses can not only enhance their innovation capabilities but also respond more agilely to market demands and changes, maintaining a competitive edge in their respective industries.

Customization and Flexibility in Design

3D printing offers unparalleled customization and flexibility in design, making it an invaluable tool for modern product development. Traditional manufacturing methods often impose limitations on design complexity and customization due to the constraints of molds and tooling. In contrast, 3D printing allows for the creation of highly intricate and personalized designs directly from digital files. This capability is particularly beneficial in industries that require bespoke solutions, such as medical devices, where patient-specific models can be produced with precision. Additionally, 3D printing enables easy modifications to existing designs without significant cost or time implications, allowing for rapid iterations and adjustments. The flexibility to experiment with different geometries, materials, and structures in a cost-effective manner encourages innovation and creativity among designers and engineers. As a result, businesses can offer more tailored products to their customers, enhancing user experience and satisfaction while also differentiating themselves in the marketplace.

Rapid Prototyping with 3D Printing

Shortening the Design Cycle

3D printing plays a crucial role in shortening the design cycle, a key advantage of rapid prototyping. Traditional prototyping methods can be lengthy, often involving multiple stages of design, fabrication, and testing, each with its associated delays. In contrast, 3D printing allows for the rapid production of prototypes directly from digital models, significantly reducing the time required for each iteration. This immediate feedback loop enables designers and engineers to quickly test and refine their concepts, leading to faster decision-making and fewer development bottlenecks. Additionally, the ability to produce functional prototypes means that real-world testing can be conducted earlier in the design process, identifying potential issues before they become costly problems. This accelerated cycle not only shortens development timelines but also improves the overall quality of the final product. By integrating 3D printing into their prototyping processes, companies can achieve more efficient and effective product development, staying ahead in competitive markets.

Reducing Time to Market

3D printing significantly reduces time to market, a critical factor for success in today’s fast-paced industries. Conventional manufacturing methods involve lengthy processes such as tooling, mold creation, and assembly line setup, which can delay product launches. In contrast, 3D printing eliminates the need for these time-consuming steps, allowing products to be designed, prototyped, and produced in a fraction of the time. This rapid turnaround means that companies can respond more swiftly to market demands and opportunities, launching new products faster than their competitors. Additionally, the ability to quickly produce and test prototypes ensures that any design flaws are identified and corrected early, avoiding costly delays later in the production cycle. By integrating 3D printing into their development processes, businesses can streamline their workflows, reduce lead times, and enhance their agility. This capability not only improves operational efficiency but also positions companies to capitalize on market trends and consumer preferences more effectively.

Enhancing Iterative Testing and Feedback

3D printing significantly enhances iterative testing and feedback, a vital component of successful product development. Traditional prototyping methods can be slow and expensive, limiting the number of iterations a design can undergo. With 3D printing, prototypes can be produced quickly and cost-effectively, enabling designers and engineers to test multiple variations in a short period. This rapid iteration process allows for immediate feedback, facilitating quicker decision-making and refinement of designs. Functional prototypes created through 3D printing can be tested in real-world conditions, providing valuable insights into performance and usability. This hands-on evaluation helps in identifying potential issues early, ensuring that only the most optimized and reliable versions progress to the final stages of development. Additionally, the ability to incorporate feedback swiftly into new iterations ensures that the final product meets or exceeds user expectations. By leveraging 3D printing for iterative testing, businesses can enhance their product quality, innovation, and overall market readiness.

3D Printing in Product Development

Streamlining the R&D Process

3D printing streamlines the Research and Development (R&D) process, making it more efficient and cost-effective. Traditional R&D often involves multiple stages of design, prototyping, and testing, each requiring significant time and resources. 3D printing simplifies this cycle by enabling direct production of prototypes from digital models, bypassing the need for complex tooling and mold creation. This capability allows R&D teams to quickly test and iterate on new designs, accelerating the discovery and refinement of innovative solutions. Moreover, the flexibility of 3D printing means that a wide range of materials and geometries can be explored without the need for extensive retooling, fostering greater experimentation and creativity. Rapid prototyping also facilitates real-time collaboration among cross-functional teams, as changes can be implemented and tested on the fly. By integrating 3D printing into the R&D process, companies can reduce development time, lower costs, and enhance their capacity for innovation, ultimately leading to more successful product outcomes.

Improving Product Quality and Performance

3D printing plays a pivotal role in improving product quality and performance during the development phase. Traditional manufacturing methods can sometimes limit the complexity and precision of designs due to tooling constraints. In contrast, 3D printing allows for the creation of intricate and highly detailed prototypes, enabling more accurate testing and validation of product features. This high level of precision ensures that design flaws are identified and corrected early in the development process, leading to higher quality end products. Additionally, 3D printing facilitates the use of advanced materials and innovative structures that can enhance the performance and durability of the final product. The ability to rapidly produce and test these variations ensures that only the most effective designs move forward. By enabling thorough testing and refinement, 3D printing helps companies achieve superior product performance, reliability, and customer satisfaction, ultimately driving competitive advantage in the market.

Case Studies and Success Stories

Numerous case studies and success stories highlight the transformative impact of 3D printing in product development. For instance, automotive companies like Ford have leveraged 3D printing to create custom tools and components, significantly reducing production costs and time. In the healthcare sector, 3D printing has enabled the development of patient-specific implants and prosthetics, leading to better patient outcomes and improved quality of life. Aerospace giants such as Boeing and Airbus utilize 3D printing to manufacture lightweight yet robust parts, enhancing aircraft performance and fuel efficiency. Consumer electronics firms have also adopted 3D printing to accelerate the prototyping and testing of new gadgets, ensuring faster time-to-market. These real-world examples demonstrate how 3D printing can drive innovation, efficiency, and competitive advantage across various industries. By adopting 3D printing technologies, businesses can achieve remarkable improvements in product development, from initial design to final production, ultimately delivering superior products to their customers.

Future of Additive Manufacturing

Emerging Technologies and Innovations

The future of additive manufacturing is brimming with emerging technologies and innovations that promise to further revolutionize the field. One notable advancement is the development of multi-material 3D printing, which allows for the simultaneous use of different materials within a single print. This opens up new possibilities for creating complex, functional products with varied properties. Another exciting innovation is the integration of artificial intelligence and machine learning algorithms to optimize printing processes, enhance quality control, and predict maintenance needs. Additionally, research into new printable materials, such as conductive inks for electronic components and bio-inks for tissue engineering, is expanding the applications of 3D printing. High-speed 3D printing technologies are also being developed, significantly reducing production times and making additive manufacturing more viable for mass production. These emerging technologies and innovations highlight the ongoing evolution and potential of 3D printing, positioning it as a cornerstone of future manufacturing and product development strategies.

Industry Applications and Opportunities

The future of additive manufacturing presents vast opportunities across various industries, driving innovation and efficiency. In healthcare, 3D printing is set to revolutionize personalized medicine with the creation of custom prosthetics, implants, and even bioprinted organs. The aerospace industry will benefit from lightweight, high-strength components that enhance fuel efficiency and performance. Automotive manufacturers are exploring 3D printing for producing custom parts and reducing assembly times, thereby streamlining production processes. In the consumer goods sector, companies are leveraging 3D printing to offer customized products tailored to individual preferences, enhancing customer satisfaction. Additionally, the construction industry is beginning to adopt large-scale 3D printing for building complex structures more quickly and cost-effectively. These applications demonstrate the broad scope and potential of 3D printing to transform traditional manufacturing paradigms. As technology advances, new opportunities will continue to emerge, solidifying additive manufacturing as a critical tool for future industrial innovation and growth.

Preparing for the Next Wave of Advancements

As the field of additive manufacturing continues to evolve, businesses must prepare for the next wave of advancements to stay competitive. Investing in the latest 3D printing technologies and materials is crucial for driving innovation and efficiency. Companies should also focus on upskilling their workforce, providing training in new techniques and tools to fully leverage the capabilities of advanced 3D printing. Collaborating with research institutions and industry partners can foster knowledge exchange and accelerate the adoption of cutting-edge developments. Additionally, integrating digital transformation strategies, such as the use of AI and machine learning for process optimization, can further enhance productivity and quality. Staying informed about emerging trends and regulatory changes will help businesses adapt and capitalize on new opportunities. By proactively embracing these advancements, companies can position themselves at the forefront of the additive manufacturing revolution, ensuring they remain leaders in their respective industries.