Product development is the backbone of innovation and a critical process for entrepreneurs aiming to transform ideas into market-ready solutions. It involves several key stages, each requiring strategic planning, collaboration, and a deep understanding of market needs. In this article, we’ll provide a detailed roadmap for entrepreneurs, exploring the essential stages of product development, strategies for overcoming challenges, and actionable tips for success.

What Is Product Development?

At its core, product development encompasses all activities involved in bringing a new product to market or enhancing an existing one. It bridges the gap between an initial idea and a tangible product that meets customer needs.

For entrepreneurs, mastering product development is not just about creating something unique—it’s about delivering value, staying competitive, and ensuring long-term business growth.

Stage 1 – Idea Generation and Validation

Every successful product starts with a strong idea. However, not all ideas are worth pursuing. The first stage of product development focuses on generating innovative concepts and validating their potential.

Brainstorming Innovative Ideas

Team Collaboration: Involve a diverse team to bring different perspectives.

Customer Insights: Talk to potential customers to understand their pain points and desires.

Market Trends: Stay updated on emerging trends and technologies in your industry.

Conducting Market Research

Market research is crucial for identifying demand and understanding the competitive landscape. Key steps include:

- Analyzing competitors’ products and strategies.

- Identifying gaps in the market.

- Assessing your target audience’s needs, preferences, and purchasing behavior.

Feasibility Study

Once you have a promising idea, evaluate its feasibility:

Technical Feasibility: Can the product be realistically designed and manufactured?

Financial Viability: Will the product generate sufficient revenue to justify the costs?

Regulatory Requirements: Are there any legal or compliance barriers?

Stage 2 – Concept Development and Design

Once an idea is validated, the next step is turning it into a concrete concept. This stage lays the foundation for product design and functionality.

Defining the Product Concept

Core Features: List the essential features your product must have to address customer needs.

Unique Selling Points (USPs): Identify what sets your product apart from competitors.

User Experience (UX): Consider how customers will interact with your product.

Design for Manufacturability (DFM)

Designing with manufacturability in mind ensures cost-efficiency and ease of production.

- Simplify the design to reduce complexity and production costs.

- Use standard components wherever possible to streamline sourcing.

- Test materials to balance cost, durability, and performance.

Prototyping

Prototypes allow you to test your concept in the real world. Options include:

- 3D Printing: Ideal for creating quick, low-cost prototypes.

- CNC Machining: Produces highly precise prototypes for functional testing.

- Custom Assembly: Combines standard and bespoke components.

Iterate the design based on feedback from stakeholders and potential customers.

Stage 3 – Development and Testing

The development stage transforms the concept into a working product. This is also where rigorous testing ensures the product meets quality and performance standards.

Building the Prototype

Collaborate with engineers and designers to create a fully functional prototype. At this stage:

- Finalize materials and components.

- Ensure compatibility of different parts.

- Use scalable methods for production readiness.

- Testing and Iteration

Test your prototype for:

- Functionality: Does the product perform as intended?

- Durability: Can it withstand expected use cases?

- Compliance: Does it meet industry standards and regulations?

Gather feedback, make necessary improvements, and repeat the testing process until the product is ready for production.

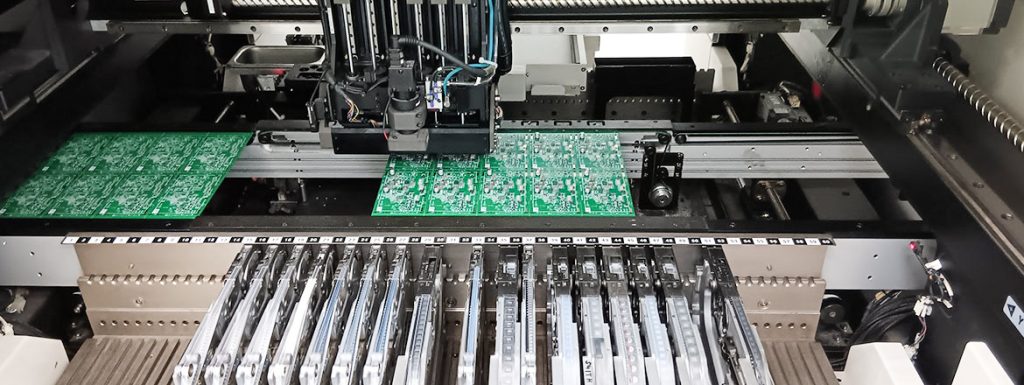

Stage 4 – Production Planning and Manufacturing

With a finalized product design, you can move on to planning its production.

Sourcing Materials and Components

- Reliable suppliers are essential for maintaining quality and meeting deadlines.

- Research suppliers with a strong track record.

- Negotiate pricing and lead times.

- Ensure suppliers meet relevant certifications (e.g., ISO 9001, RoHS).

Choosing the Right Manufacturer

Factors to consider when selecting a manufacturer include:

- Production capabilities: Can they handle your required volume and complexity?

- Location: Manufacturing hubs like Malaysia offer skilled labor and infrastructure, while regions like Vietnam, India, and Mexico may pose challenges like labor cost inflation or regulatory hurdles.

- Quality control processes: Ensure the manufacturer has robust quality assurance practices in place.

Implementing Quality Assurance

Establishing quality control (QC) measures ensures consistent product standards.

- Conduct inspections at every stage of production.

- Use sampling techniques to check for defects.

- Maintain open communication with manufacturers to address issues promptly.

Stage 5 – Market Launch and Distribution

After production, it’s time to bring your product to market. This stage involves careful planning to maximize impact.

Preparing for Launch

Develop a marketing strategy to create awareness and excitement.

- Train your sales team to effectively communicate the product’s benefits.

- Create a product launch plan with clear timelines and deliverables.

Distribution Channels

Decide how your product will reach customers:

- Direct-to-Consumer (DTC): Sell through your website or online platforms.

- Retail: Partner with brick-and-mortar stores or online marketplaces.

- Wholesale: Work with distributors to reach a broader market.

Customer Feedback

Collect feedback post-launch to identify areas for improvement. This information can guide future iterations or entirely new products.

Overcoming Challenges in Product Development

Common Obstacles

- Design Flaws: Address through rigorous testing and iteration.

- Manufacturing Delays: Work with reliable suppliers and maintain buffer timelines.

- Budget Overruns: Monitor expenses closely and plan for contingencies.

- Adapting to Challenges: Flexibility and problem-solving are essential for overcoming hurdles. Build a strong team and maintain open communication with all stakeholders to navigate challenges effectively.

Final Tips for Successful Product Development

Focus on Collaboration

Involve cross-functional teams from engineering, marketing, and sales early in the process to ensure alignment and better decision-making.

Leverage Technology

Use tools like project management software, CAD systems, and rapid prototyping technologies to streamline workflows and improve efficiency.

Stay Customer-Centric

Keep the end user in mind at every stage of product development. Regularly engage with potential customers to validate your assumptions and refine the product.

Iterate and Innovate

Product development is an ongoing process. Continuously seek feedback, innovate, and adapt to market changes to stay competitive.

Product development is a dynamic and iterative process that requires careful planning, collaboration, and adaptability. From idea generation and design to manufacturing and market launch, each stage plays a vital role in creating a successful product.

For entrepreneurs, understanding the nuances of product development is key to transforming innovative ideas into tangible solutions that meet customer needs and drive business growth. By following this roadmap, you’ll be better equipped to navigate challenges, optimize processes, and bring impactful products to market.