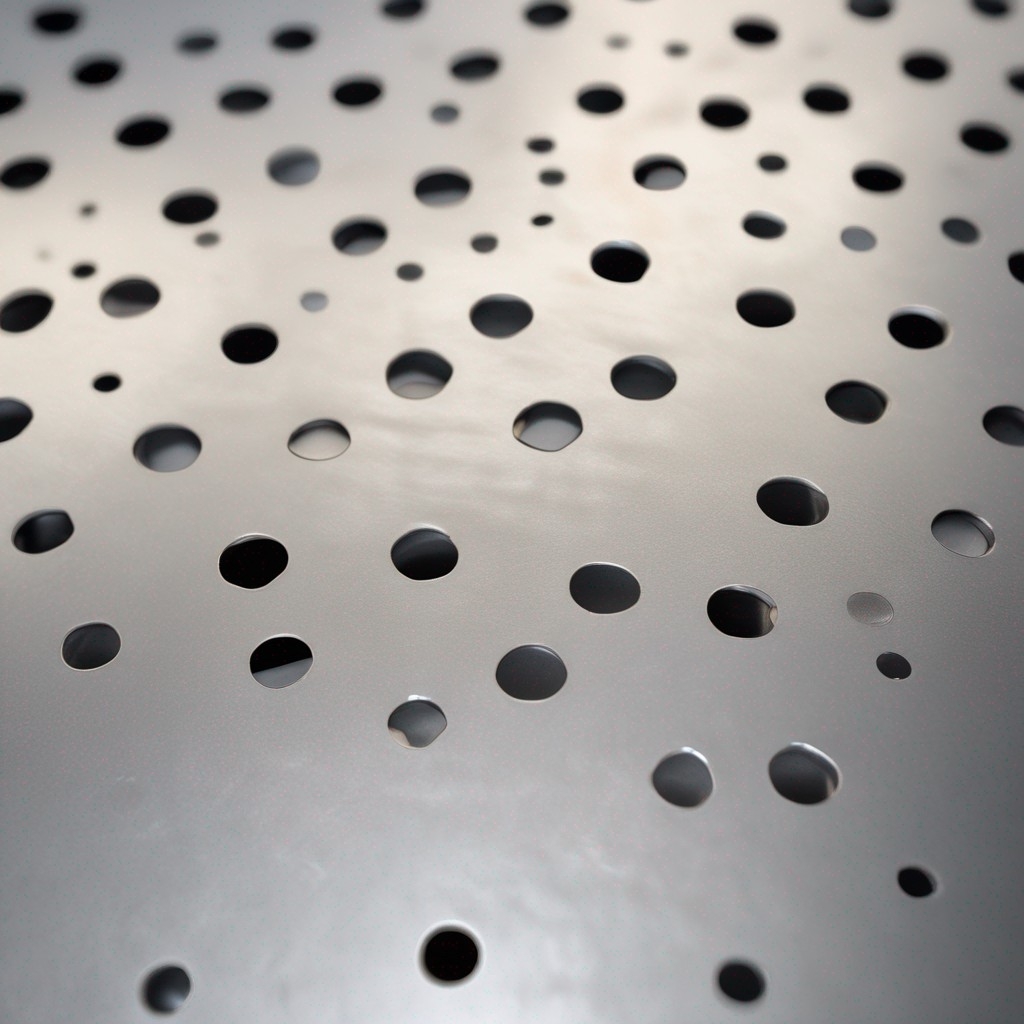

Another important machine frequently used in sheet metal fabrication, is the Turret punch. Turret punch (also known as a turret press) is a high-speed press machine equipped with a variety of standard punch tools. These tools cater for a wide range of hole shapes and sizes.

The term “turret” refers to the holders which can be precisely programmed to rotate and load the required punch and die. Through its advanced control system, both turrets can be configured to move and rotate in sync to any specific position.

CNC Turret punch machines are usually equipped with two turrets with each housing a set of punches and dies. In most machines, each turret is able to hold at least 40 different toolsets.

The turret punch machine simulates the typical blanking or piercing process of a standard press machine for the relatively small and standard shapes. Whereas for much bigger and complex shapes, it is done by incrementally “punching” the shape of the material. In other words, instead of “punching” all the holes and shapes in a single shot, the turret punch machine utilises its advanced control system to precisely fabricate the metal parts in a series of high-speed strokes.

A conventional press machine has its limitations when wanting to punching holes. As opposed to the standard press machine, turret punch eliminates the need for a high cost investment in product-specific tooling. Capitalising on its wide range of tool shapes and features, turret punch addresses these cost-related constraints that are commonly faced by manufacturers particularly for low-volume products.

Isn’t laser cutting more flexible and easier than turret punching?

Each of laser cut and turret punch as each have their own strengths and weaknesses. When it comes to profiles with repeating straight-forward shapes and holes, turret punch is the obvious winner. Without the need to deal with additional costs in laser gases, ventilation and maintenance, turret punch supersedes the laser cut process through its high-speed punching mechanism and low setup cost. Not to mention that turret punch eliminates the risk of thermal distortion in thin material sheet due to laser heat exposure.

Having turret punching for sheet metal fabrication as a supplement to traditional laser cutting machine reduces cost and improves efficiencies and accuracy.

A typical turret punch is capable of the following:

- Punching capacity: 30 ton

- Max sheet size: 1525x3050mm

- Max thickness: 6.35mm

- Nibbling speed: 600 hits/min

- Number of tool stations: 40

- Max ram stroke distance: 31mm

- Punching accuracy: +/- 0.1mm