In the ever-evolving landscape of manufacturing, the precision of mold flow analysis in injection molding is a game-changer for industry innovators seeking to refine their production processes. Mold flow analysis is a critical component of the design for manufacturing process that allows engineers to predict how melted plastic will behave in a mold cavity, ensuring optimal quality and efficiency. This sophisticated simulation technique is crucial for identifying potential defects, minimizing material waste, and reducing time-to-market. By leveraging advanced mold flow analysis services, businesses can enhance product performance and gain a competitive edge. In this exploration, we will delve into the intricacies of mold flow analysis, underscoring its importance and the profound impact it has on the manufacturing sector.

Understanding Moldflow Analysis

What is Moldflow Analysis?

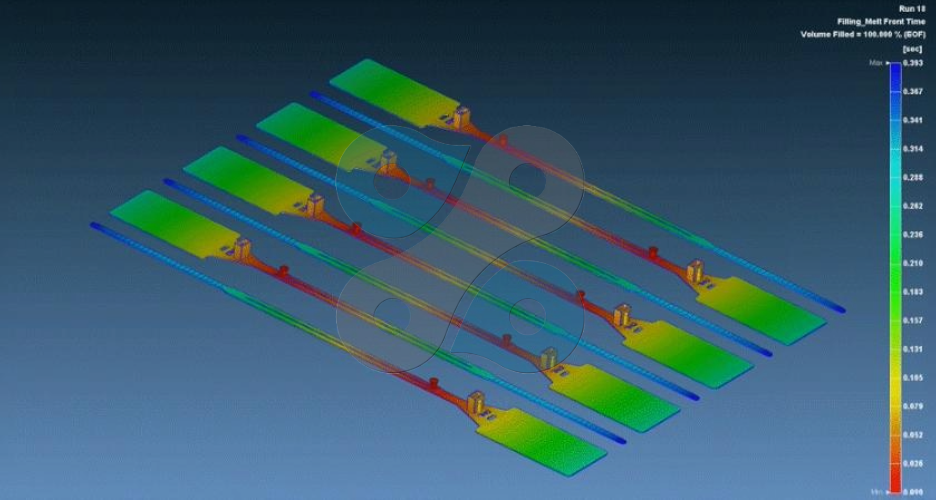

Moldflow analysis is a sophisticated simulation process used in injection molding to predict the behavior of molten plastic within a mold cavity. This technique utilizes advanced computational tools to model the flow, cooling, and solidification of plastic materials during the injection molding process. By simulating these dynamics, engineers can anticipate potential issues, such as air traps, weld lines, or excessive shrinkage, long before actual production begins. This predictive ability is critical for optimizing mold designs, ensuring product quality, and enhancing manufacturing efficiency. The results gleaned from mold flow analysis guide critical decision-making in the design phase, allowing for adjustments that reduce cycle times, minimize defects, and decrease material waste. Businesses leveraging mold flow analysis services can gain insights that lead to improved product performance and reduced costs, making it an indispensable tool in the manufacturing industry.

Importance in Injection Moulding

Moldflow analysis plays a crucial role in the injection molding process by facilitating precision and efficiency. It allows manufacturers to visualize potential problems and refine their designs before production, thereby reducing costly errors. By identifying issues such as incomplete fills, warping, or sink marks early on, companies can make necessary adjustments to the mold design or processing conditions. This level of foresight not only helps in improving product quality but also significantly speeds up the time-to-market. Additionally, mold flow analysis aids in optimizing material usage, which can result in substantial cost savings. In a competitive manufacturing landscape, these advantages are vital. Utilizing mold flow analysis services ensures that businesses maintain a high standard of quality and remain agile in responding to market demands. Thus, moldflow analysis is indispensable for companies striving for innovation and excellence in injection molding.

Key Benefits for Manufacturers

Moldflow analysis offers numerous benefits to manufacturers that can greatly enhance their production processes. One of the primary advantages is the ability to predict and mitigate potential defects before they occur, such as air pockets, weld lines, and warpage. This proactive approach leads to higher quality products and fewer production delays. Additionally, mold flow analysis helps in optimizing the mold design and processing parameters, which can reduce cycle times and increase production efficiency.

Another significant benefit is the reduction in material waste. By accurately predicting how the molten plastic will flow and solidify, manufacturers can fine-tune the amount of material used, leading to substantial cost savings. Furthermore, mold flow analysis services enable faster time-to-market by streamlining the development process and reducing the need for multiple iterations of physical prototypes. These benefits collectively provide manufacturers with a competitive edge, ensuring they can meet market demands swiftly and effectively.

Accuracy in Moldflow Analysis

Factors Affecting Precision

The precision of moldflow analysis can be influenced by various factors, which are crucial for achieving accurate predictions in injection molding. One key factor is the quality of the input data. Accurate material properties, such as viscosity, thermal conductivity, and specific heat, are essential for reliable simulation results. Additionally, the geometric complexity of the mold and the fidelity of the mesh used in the simulation can impact accuracy. A finer mesh typically provides more detailed results but requires greater computational resources.

Another important consideration is the completeness of the process parameters. Factors like injection speed, pressure, and temperature profiles should be precisely defined to mirror real-world conditions. Moreover, software capabilities and the expertise of the engineers conducting the analysis also play significant roles. Advanced moldflow analysis services often employ cutting-edge software and skilled analysts to enhance precision. By carefully managing these factors, manufacturers can ensure that the moldflow analysis provides valuable insights and improvements.

Comparing Moldflow Analysis Services

When evaluating moldflow analysis services, several factors should be considered to ensure optimal results. First, assess the software tools used by the service provider. Leading-edge software that supports advanced simulation capabilities often yields more accurate and reliable results. Additionally, consider the provider’s expertise and experience, as skilled engineers can significantly enhance the quality of the analysis through their insights and attention to detail.

Service customization is another critical aspect. Different projects may require tailored solutions based on specific materials, geometries, or production goals. Providers offering flexible analysis options can better accommodate unique project requirements. Furthermore, timely delivery of results is essential in fast-paced manufacturing environments, so evaluating a provider’s turnaround time is crucial.

Lastly, consider the level of support and communication offered throughout the process. Clear and consistent communication can facilitate better collaboration and ensure that the analysis aligns with your objectives. Comparing these aspects will help in selecting a service that best meets your manufacturing needs.

Case Studies and Real-World Examples

The impact of moldflow analysis in real-world scenarios can be profound, as evidenced by numerous case studies across various industries. For instance, an automotive manufacturer leveraged moldflow analysis to redesign a component that was prone to warping. By simulating different mold designs and process conditions, they identified a solution that reduced the defect rate by 30%, significantly improving the component’s reliability and performance.

In the consumer electronics sector, a company faced challenges with incomplete fills in a complex housing unit. Through detailed moldflow analysis, they optimized gate locations and adjusted the injection speed, resulting in a 20% reduction in production time and substantial material savings.

Similarly, a medical device manufacturer used moldflow analysis services to refine a small, intricate part. The analysis enabled them to predict potential weld lines and adjust the mold design accordingly, enhancing the part’s structural integrity. These examples highlight how moldflow analysis can drive innovation and efficiency in diverse manufacturing contexts.

Integrating Moldflow in Design Process

Enhancing Design for Manufacturing

Integrating moldflow analysis into the design for manufacturing (DFM) process significantly enhances product development by preemptively addressing potential production issues. By incorporating this analysis early in the design phase, engineers can make informed decisions that improve manufacturability and product quality. The insights gained from moldflow simulations allow for the optimization of mold design, such as adjusting wall thickness, modifying gate locations, and refining material flow paths.

One of the main advantages is the reduction of costly design revisions. By identifying and resolving issues before physical prototyping, manufacturers can avoid time-consuming and expensive adjustments. Additionally, moldflow analysis enables the exploration of various design alternatives, helping to identify the most efficient and cost-effective solutions.

This proactive approach not only shortens the development cycle but also ensures that the final product meets performance and quality standards. As a result, integrating moldflow analysis in the DFM process empowers manufacturers to deliver superior products with increased speed and reduced costs.