Tag: Design and Development

-

Unlock Your Startup with Vohrum: Expert Custom Product Development Services

In the dynamic world of entrepreneurship, turning a groundbreaking idea into a market-ready product requires more than just vision; it demands precision, expertise, and resilience. This is where Vohrum steps in as your trusted partner in custom product development, offering tailored solutions designed to navigate the complexities of innovative product design. With an expert team…

-

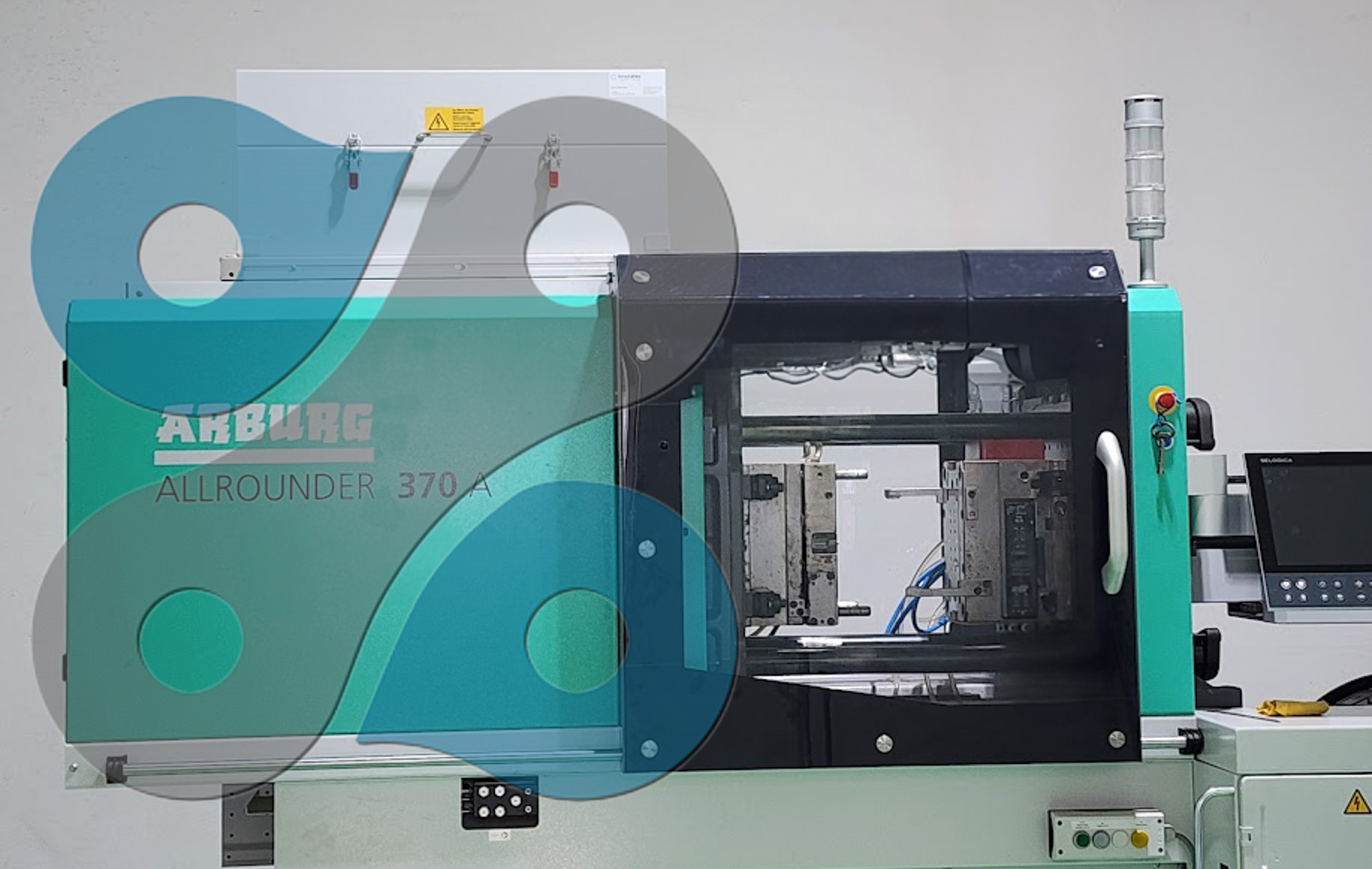

Mastering Process Robustness: The Role of Concurrent Engineering in Plastic Injection Moulding

In the competitive world of manufacturing, achieving process robustness in plastic injection moulding is a pivotal factor for ensuring part quality consistency and manufacturing efficiency. Concurrent engineering emerges as a key strategy for addressing the complex challenges inherent in the moulding process, facilitating seamless collaboration across design, engineering, and production teams. By integrating concurrent engineering…

-

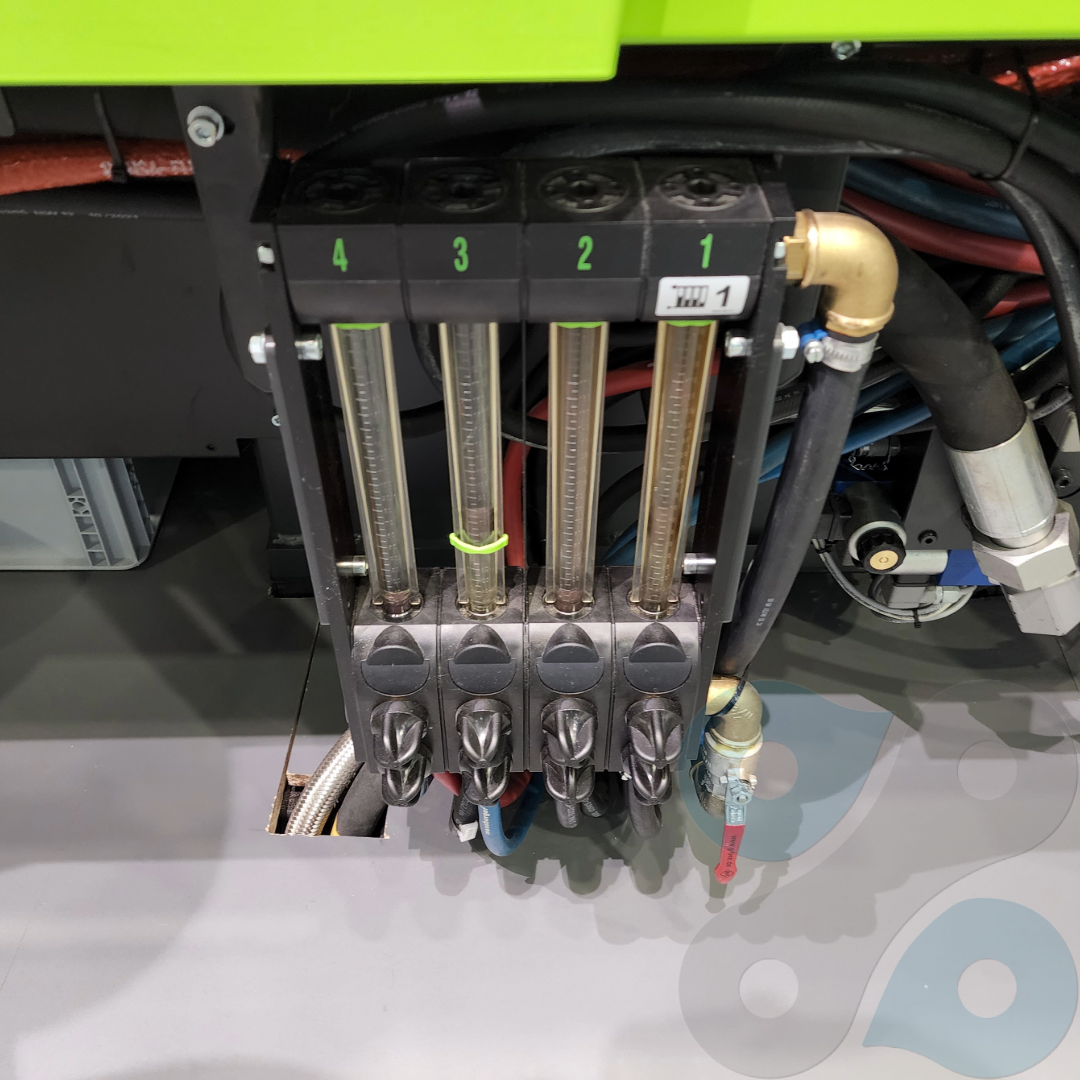

Unlocking Excellence: How Optimized Cooling Transforms Injection Moulding for Superior Quality and Speed

In the competitive world of plastic manufacturing, the cooling process in injection moulding stands as a pivotal factor influencing both the quality and speed of production. By optimizing this phase, manufacturers can achieve significant improvements in manufacturing efficiency and dimensional accuracy, ultimately leading to superior molded parts quality. Properly managed cooling reduces production speed and…

-

The Science Behind Perfection: Elevating Product Development with Advanced Injection Molding Techniques

In the ever-evolving landscape of product development, achieving perfection is not just an aspiration but a necessity for maintaining competitive advantage. The advent of scientific molding has revolutionized the way manufacturers optimize their molding techniques, leading to enhanced product quality and efficiency in manufacturing processes. By employing precise data-driven methodologies, scientific molding allows for meticulous…

-

The Power of Empathy: Enhancing Your Product Design and Development Process with Design Thinking

In the ever-evolving landscape of product design and development, design thinking emerges as a powerful methodology that champions empathy to enhance the product design and development process. This human-centric approach is pivotal for teams aiming to innovate and create solutions that resonate with end-users, particularly in industries like medical devices, pharmaceuticals, cosmetics, and allied healthcare.…

-

Product Design & Development here in Asia: Boosting Manufacturing with Rapid Prototyping and CAD

Product Design & Development in Asia is experiencing a significant transformation, driven by the adoption of rapid prototyping and computer-aided design (CAD) technologies. These cutting-edge tools are revolutionizing the manufacturing landscape, enabling companies to accelerate product development cycles, enhance precision, and reduce time-to-market. In this piece, we will delve into how these innovations are being…

-

Unleashing Innovation: How Design Thinking Transforms Product Design and Development

Unleashing Innovation through design thinking is revolutionizing the product design and development landscape, particularly within the medical device, pharmaceutical, cosmetic, and allied healthcare industries. This human-centric approach empowers teams to empathize with users, precisely define challenges, ideate innovative solutions, and rigorously prototype and test concepts. By integrating design thinking into the product design and development…

-

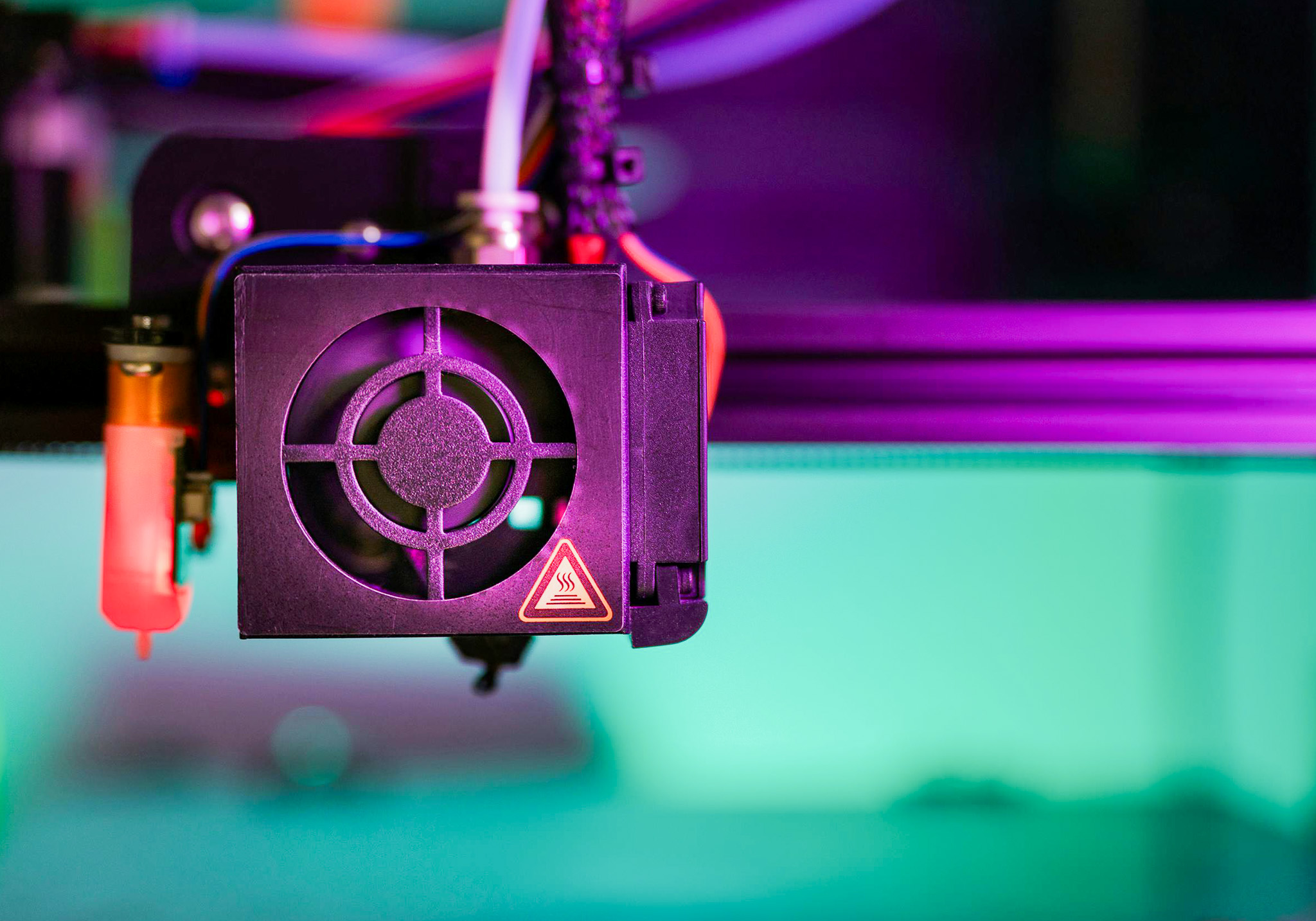

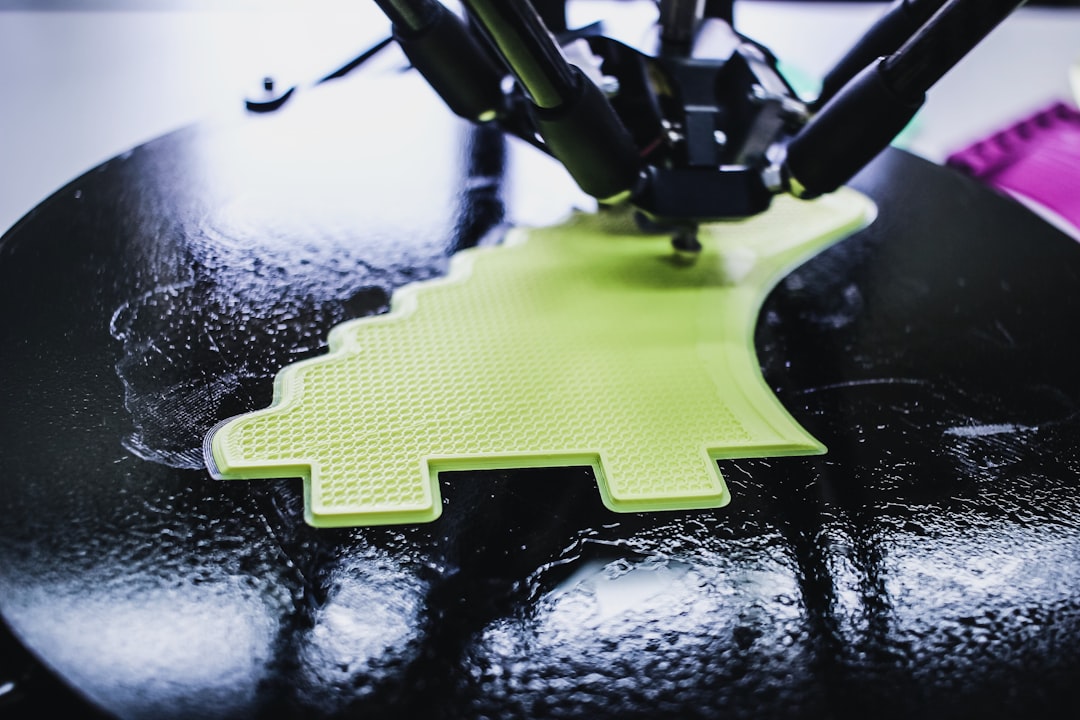

Unlocking Innovation: The Benefits of 3D Printing for Rapid Prototyping and Product Development

In the fast-paced world of product design and development, the integration of 3D printing technology has revolutionized the way companies approach rapid prototyping and product development. This cutting-edge additive manufacturing technique offers myriad benefits, enabling engineers and designers to iterate quickly, reduce costs, and accelerate time-to-market. By harnessing the power of 3D printing, businesses can…

-

Overcoming Rapid Product Development Challenges with Innovative Solutions

In the fast-paced world of manufacturing, overcoming rapid product development challenges is crucial for staying competitive and meeting market demands. Leveraging innovative solutions such as computer-aided design (CAD), simulation software, and rapid prototyping can significantly enhance the efficiency and quality of the design process. These advanced tools not only streamline development but also help in…

-

How Design Development Solutions Drive Superior Product Quality

Design development solutions are pivotal in driving superior product quality and fostering innovation within the manufacturing sector. By employing advanced techniques such as computer-aided design (CAD), simulation software, and rapid prototyping, companies can streamline their design processes, preemptively address potential issues, and optimize product performance. In this article, we will delve into various design development…

-

How CT Scanning allows for accurate and permanent digital representation of the scanned part

CT scanning in industrial applications allows for digital representation of the scanned part by converting a physical part to 3D. This process offers various benefits that contribute to improved efficiency, accuracy, and quality in manufacturing and inspection processes. Digital copies of CT scans can be archived for future reference, providing a comprehensive record of inspection…

-

Non-destructive testing: what is it and why use it?

Why is CT Scanning considered a “non-destructive testing” method? What is “non-destructive”? CT Scanning is considered a non-destructive inspection technique because it allows for the visualization of the internal structure of an object without causing any physical damage to the object itself. In non-destructive testing (NDT), the goal is to examine and evaluate the integrity,…

-

Reverse engineering your products: whether an assembled product, or components like plastic or metal parts

We study and propose reverse engineer for your product, be it an entire assembly or at component level like metal, plastic (via injection molding or other processes), die-casting, CNC machining and other components parts by looking at a re-design, re-engineer, mold-flow analysis, modifications and manufacturability. We work with customers to develop new products, rapid prototyping,…