-

De voordelen van Snap Fit-montage voor innovatief ontwerp van kunststofproducten ontsluiten

In today’s fast-paced world of manufacturing and product design, the demand for innovative and efficient assembly techniques has never been higher. As companies seek welding alternatives for plastics and strive to reduce reliance on traditional fastening methods, snap fit design emerges as a promising solution. This technique, which involves the interlocking of plastic parts without

-

Het volledige potentieel van Surface Mount Technology ontsluiten: tips en technieken voor efficiënte implementatie

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by enabling the creation of compact, high-performance devices with increased reliability. As a SMT company and leader in the field, we are committed to helping engineers, technicians, and students unlock the full potential of SMT through expert guidance and advanced techniques. In this document, we

-

De ultieme gids voor prototypetechnieken: de voor- en nadelen van kunststofonderdelen afwegen

In the ever-evolving landscape of manufacturing and design, selecting the right prototype techniques for plastic parts is crucial for product owners, engineers, designers, and manufacturers. With a myriad of options available, including 3D printing, CNC machining, prototype tooling for injection moulding, and vacuum casting, it becomes essential to weigh the pros and cons of each

-

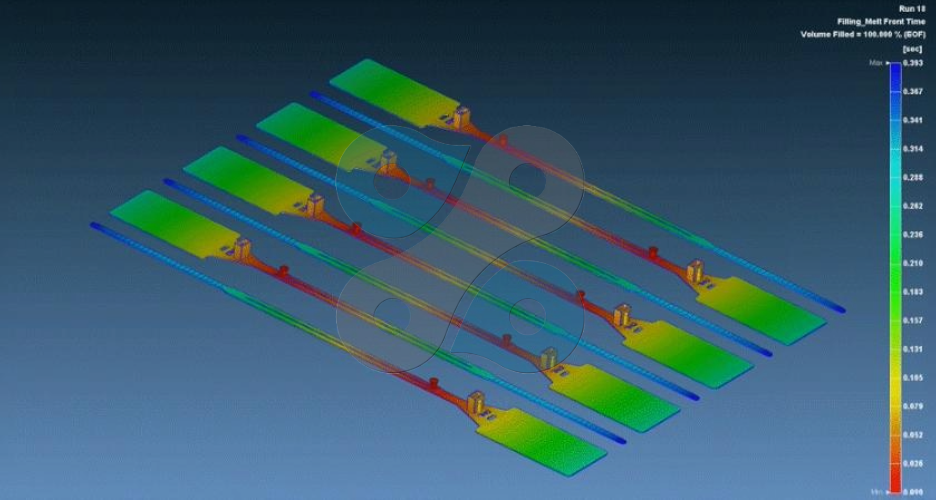

De precisie van Moldflow-analyse bij spuitgieten: een diepgaande duik voor industriële vernieuwers

In the ever-evolving landscape of manufacturing, the precision of mold flow analysis in injection molding is a game-changer for industry innovators seeking to refine their production processes. Mold flow analysis is a critical component of the design for manufacturing process that allows engineers to predict how melted plastic will behave in a mold cavity, ensuring