In the competitive world of manufacturing, achieving process robustness in plastic injection moulding is a pivotal factor for ensuring part quality consistency and manufacturing efficiency. Concurrent engineering emerges as a key strategy for addressing the complex challenges inherent in the moulding process, facilitating seamless collaboration across design, engineering, and production teams. By integrating concurrent engineering practices, companies can enhance quality assurance, optimize design validation, and streamline operations to meet the exacting standards of their clients. In this article, we will delve into the five critical factors that influence part quality consistency, and explore how the adoption of concurrent engineering can lead to a robust and efficient moulding process, thereby positioning companies as leaders in the industry.

Importance of Process Robustness

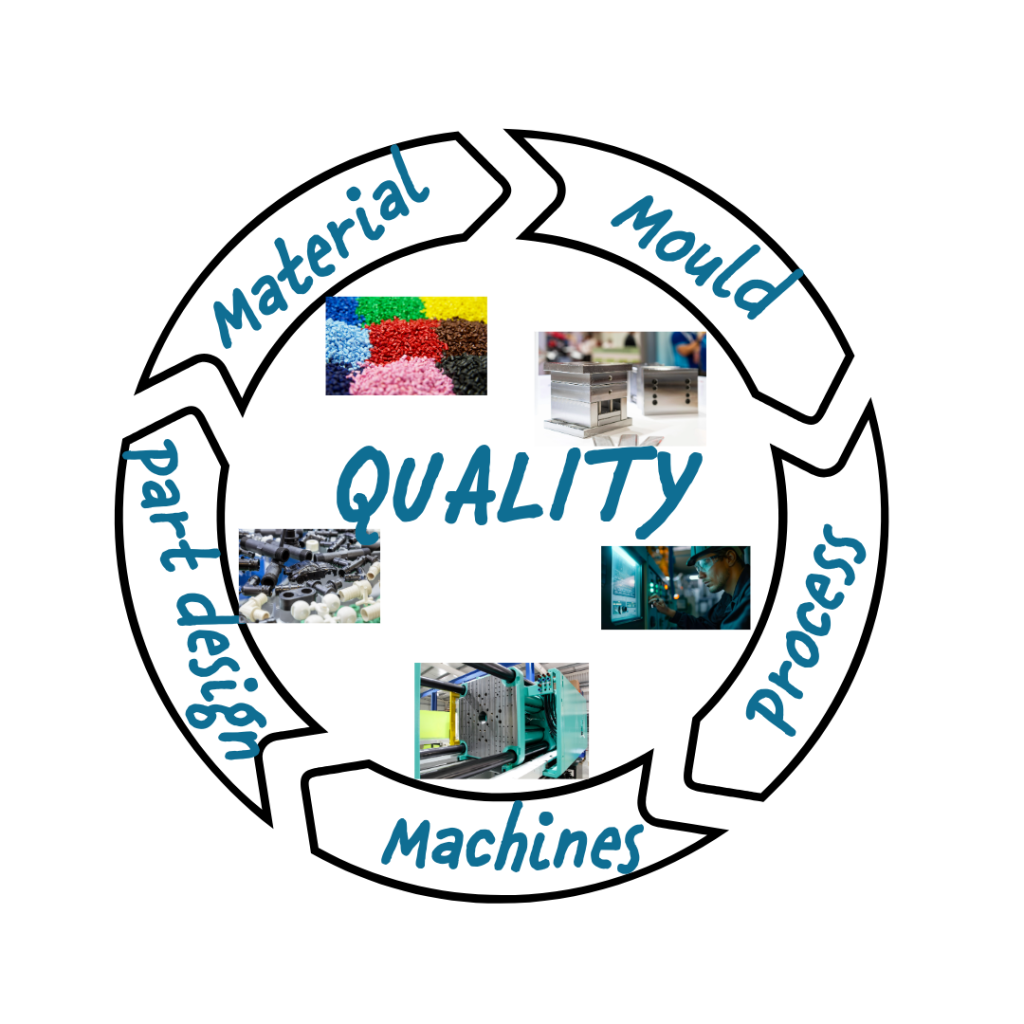

Factors Influencing Part Quality

In plastic injection moulding, part quality consistency is influenced by several critical factors. Material selection is paramount, as it impacts the strength, durability, and finish of the final product. Proper material choice ensures that parts meet required specifications and perform reliably over their lifespan. Additionally, mould design plays a crucial role. Detailed attention to cavity design, cooling channels, and ejection mechanisms is necessary to prevent defects such as warping or incomplete fills. Process parameters like temperature, pressure, and injection speed must be meticulously controlled and monitored to maintain uniformity in part production. Furthermore, equipment maintenance is essential to avoid any unexpected downtimes or malfunctions that could compromise part quality. By understanding and optimizing these factors, manufacturers can significantly improve process robustness and part quality consistency, leading to enhanced satisfaction for clients seeking high-performance plastic components.

Achieving Consistent Moulding Process

Achieving a consistent moulding process is essential for maintaining part quality consistency and manufacturing efficiency in plastic injection moulding. This consistency hinges on the alignment of design, material, and process parameters. By employing concurrent engineering, teams can work collaboratively from the outset, ensuring that design considerations align with material capabilities and process constraints. Implementing robust quality assurance protocols throughout production is crucial. This includes regular inspections and testing to identify and rectify any deviations swiftly. Moreover, leveraging advanced technologies such as predictive analytics and real-time monitoring systems can enhance process stability. These tools enable manufacturers to detect potential issues before they escalate, ensuring a seamless operation. Continuous training and skill development for staff also play a vital role, equipping them to manage and adjust processes effectively. Together, these strategies enhance the overall robustness of the moulding process, contributing to the consistent delivery of high-quality plastic parts.

Role of Concurrent Engineering

Enhancing Manufacturing Efficiency

Concurrent engineering significantly enhances manufacturing efficiency in plastic injection moulding by promoting integrated workflows and reducing time-to-market. By involving cross-functional teams early in the product development stage, companies can address potential design and process issues proactively. This collaborative approach minimizes costly redesigns and ensures that all aspects of production are aligned from the start. Concurrent engineering also facilitates better resource management. By synchronizing activities across departments, manufacturers can optimize scheduling, reduce lead times, and increase throughput. Additionally, this strategy supports continuous improvement by fostering an environment where feedback is shared and incorporated swiftly. Utilizing concurrent engineering practices allows businesses to adapt quickly to changes in demand or specifications without sacrificing quality. The efficiency gains achieved through this method not only lead to cost savings but also enhance the company’s reputation for reliability and innovation, ultimately attracting more clients interested in high-quality, precision-engineered plastic parts.

Ensuring Quality Assurance

Incorporating concurrent engineering into the plastic injection moulding process is pivotal for ensuring robust quality assurance. This approach allows for the early identification and resolution of potential quality issues, reducing the likelihood of defects in the final product. By engaging design, engineering, and quality assurance teams concurrently, companies can create more comprehensive quality control measures that address each stage of production. This collaboration ensures that all product specifications and standards are met consistently. Concurrent engineering also supports the integration of advanced quality assurance tools, such as statistical process control and automated inspection systems, which enhance the accuracy and reliability of quality assessments. Additionally, regular cross-departmental reviews facilitate the continuous monitoring and improvement of quality protocols. By prioritizing quality assurance within the concurrent engineering framework, manufacturers not only achieve higher part quality consistency but also build client trust, ultimately establishing themselves as leaders in precision and reliability in the competitive manufacturing landscape.

Strategies for Design Validation

Improving Part Quality Consistency

Improving part quality consistency through design validation is essential in the plastic injection moulding industry. Effective design validation ensures that parts are not only functional but also reliable and durable. By implementing concurrent engineering, teams can collaboratively assess and refine designs before production begins, identifying potential flaws that could affect quality. This proactive approach allows for adjustments to be made early, minimizing the risk of defects and ensuring that the final product meets all specifications. Advanced simulation tools play a crucial role in this process, enabling engineers to test and validate designs under various conditions without the need for physical prototypes. These tools help predict how materials will behave during moulding, allowing for optimization of design parameters. Furthermore, iterative testing and feedback loops involving cross-functional teams ensure continuous improvement. By focusing on design validation, manufacturers can achieve superior part quality consistency, meeting the demanding expectations of clients and strengthening their market position.

Innovations in Plastic Injection Moulding

Innovations in plastic injection moulding are revolutionizing the way manufacturers approach design validation and process robustness. One significant advancement is the use of 3D printing technologies to create detailed prototypes quickly, allowing for rapid design iterations and validation before committing to full-scale production. This accelerates the development cycle and reduces costs associated with traditional prototyping methods. Additionally, the integration of smart manufacturing technologies, such as IoT-enabled sensors and machine learning algorithms, enables real-time monitoring and analysis of the moulding process. These technologies provide valuable insights into process parameters, facilitating immediate adjustments to enhance part quality consistency. Furthermore, the development of new polymer materials with enhanced properties offers greater flexibility in design and application, expanding the possibilities for innovation in product development. By leveraging these innovations, manufacturers can not only improve their design validation strategies but also achieve higher efficiency and quality in their plastic injection moulding operations.