Design development solutions are pivotal in driving superior product quality and fostering innovation within the manufacturing sector. By employing advanced techniques such as computer-aided design (CAD), simulation software, and rapid prototyping, companies can streamline their design processes, preemptively address potential issues, and optimize product performance. In this article, we will delve into various design development solutions and illustrate how they contribute to producing high-quality, reliable products that align with market demands.

Key Design Development Solutions

Computer-Aided Design (CAD)

Computer-Aided Design (CAD) is a cornerstone in the realm of design development solutions. CAD software allows engineers and designers to create precise 2D and 3D models of products, facilitating rapid product development. This precision in modeling helps in identifying and addressing design flaws early in the process, significantly reducing the risk of costly manufacturing errors. Moreover, CAD enables easy modifications and iterations, allowing for rapid product development even in the face of evolving requirements. By leveraging CAD, companies can enhance their design accuracy, improve product quality, and accelerate time-to-market. The ability to simulate and visualize the final product in a digital space also aids in better decision-making and collaboration across teams, ensuring that the final product aligns with market demands and customer expectations.

Simulation Software Benefits

Simulation software is instrumental in addressing rapid product development challenges. By creating virtual models of products, simulation tools allow engineers to test and analyze various aspects such as structural integrity, thermal performance, and fluid dynamics without the need for physical prototypes. Mold flow analysis helps with understanding how plastic components would fill before they are even made. This not only saves time and resources but also helps in identifying potential issues early in the design phase. The ability to simulate real-world conditions ensures that the product will perform as expected, thereby enhancing reliability and quality. Additionally, simulation software facilitates rapid iterations, enabling engineers to explore multiple design alternatives and optimize for the best possible outcome. This level of detail and accuracy in the simulation process is crucial for meeting stringent industry standards and customer expectations, ultimately contributing to the production of superior products.

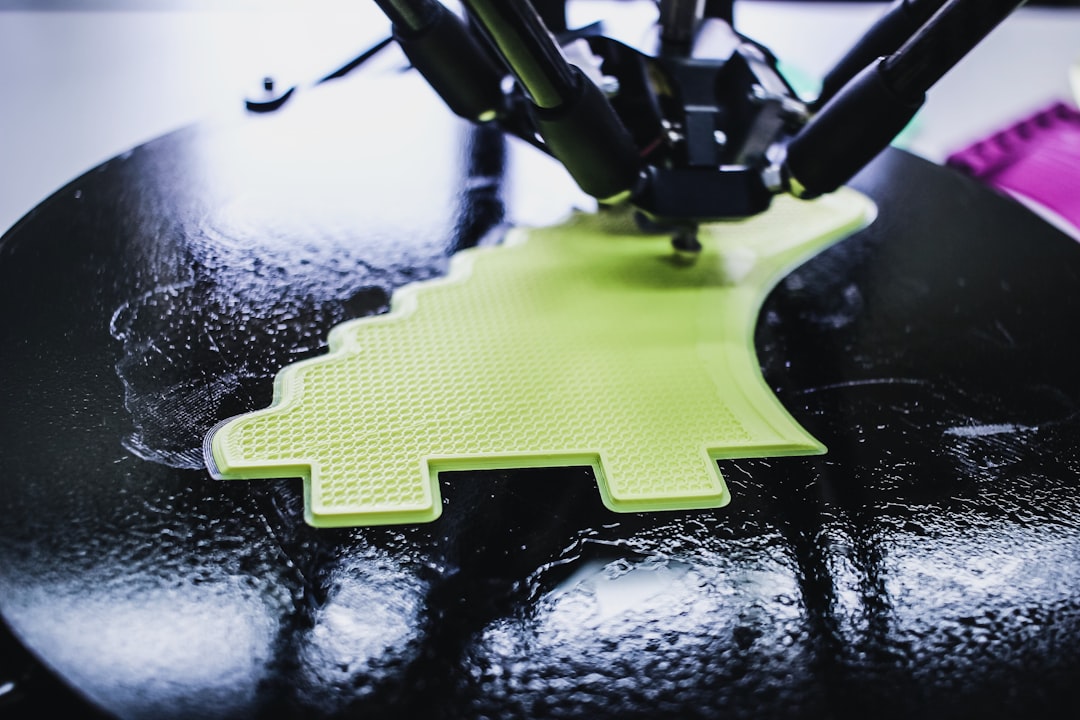

Rapid Prototyping Techniques

Rapid prototyping techniques are essential for accelerating the product development cycle. These techniques, which include 3D printing, CNC machining, and laser cutting, enable the quick creation of physical prototypes from digital models. Rapid prototyping allows engineers and designers to validate form, fit, and function early in the development process, thereby reducing the time and cost associated with traditional prototyping methods. For instance, 3D printing can produce complex geometries that would be difficult or impossible to achieve using conventional manufacturing techniques. This capability is particularly useful for testing and iterating on designs quickly, addressing rapid product development challenges effectively. By leveraging rapid prototyping, companies can bring products to market faster while ensuring they meet quality and performance standards. This approach not only enhances innovation but also provides a competitive edge in rapidly evolving markets.