-

How Design Development Solutions Drive Superior Product Quality

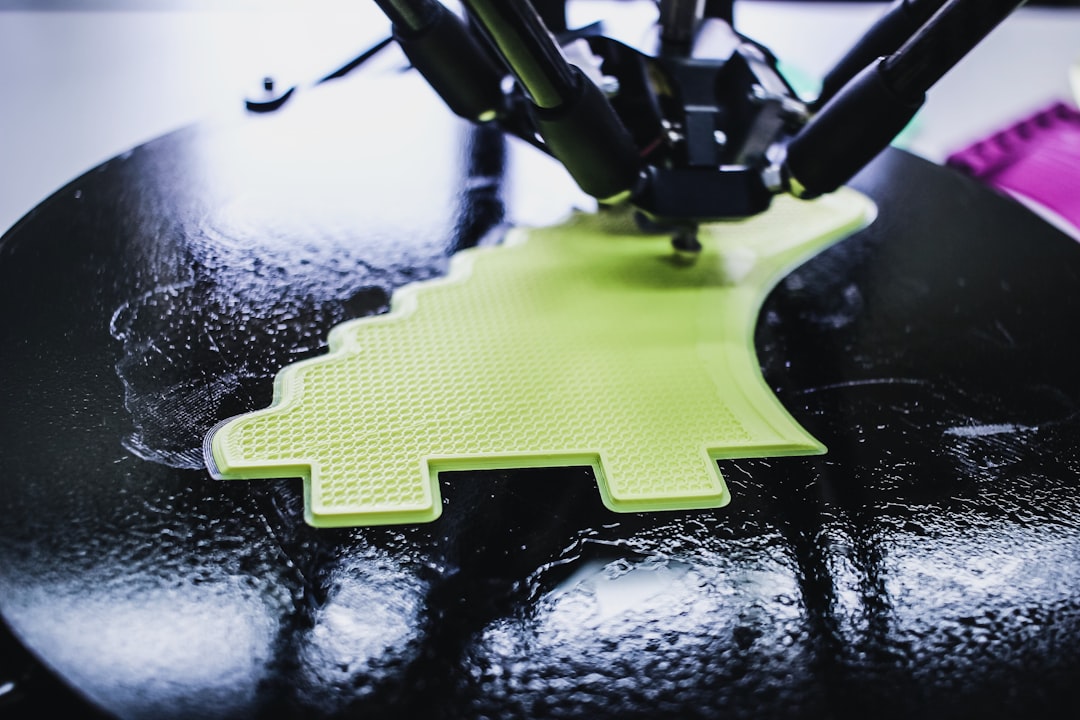

Design development solutions are pivotal in driving superior product quality and fostering innovation within the manufacturing sector. By employing advanced techniques such as computer-aided design (CAD), simulation software, and rapid prototyping, companies can streamline their design processes, preemptively address potential issues, and optimize product performance. In this article, we will delve into various design development

-

Achieving Superior Quality: The Role of Moldflow Analysis in Injection Moulding

Achieving superior quality in injection moulding necessitates a strategic focus on design for manufacturability, and this is where moldflow analysis proves indispensable. Moldflow analysis allows engineers to simulate the plastic injection moulding process, identifying potential issues and optimizing designs before production begins. By leveraging this advanced technology, companies can ensure excellence in product quality, reduce